Loadscan’s CVS featured in Australian Mining magazine

Loadscan managing director Carey West recalls getting on the back of a truck and shoveling out the load during his 20s.

His job at the time was to manage truck movements on and off construction sites for a company his late father owned.

During this time, truck drivers constantly complained about West manually measuring the amount of material carried by the truck – by standing up and pressing the material down to make it compact.

The truck drivers would say it wasn’t a true measure of how much was in there. So, in 1998, West’s father decided to make a truck volume metric scanner and called it Tally Clerk.

The scanner received trade certification in New Zealand a year later, but only in 2010 did it obtain the same certification in Australia. After all, to West’s father Tally Clerk was just a hobby business on the side of the family’s main company.

His son begs to differ, however.

“I was using the product on the construction site that I was running and could see firsthand the difference it made to operations. I really liked the product. I thought it should be sold globally,” West says.

Tally Clerk load volume scanning (LVS) systems were sold between 2009 and 2010 to a few customers in North America and the United States.

Not long after, West’s father passed away.

“The family ended up with this business called Tally Clerk that wasn’t really a business. It was just a product that my father was working with,” West says.

“So, after 20 years of being in construction, I decided to get out and make something of this innovative tool for industry. I took the LVS product and knew it had global appeal.”

And so what started out as a hobby business was taken on wholeheartedly by West. With only an engineer by his side, Tally Clerk was transformed into the company now known as Loadscan.

It now employs 13 people, with a couple more contractors also working for the company.

The story doesn’t stop there. The team has taken truck load scanners to the world, developed and improved it.

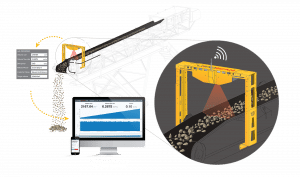

And now Loadscan has also innovated a new product called the conveyor volume scanner (CVS). Like the load volume scanner (LVS) before it, the CVS combines laser scanning with proprietary software to deliver real-time volume measurement and insightful reporting.

“This is the biggest product development that we’ve done in the last six years. And we designed it specifically for the market, because we have been asked if it would be possible to make a belt scanner many times in the past,” West continues.

Loadscan took inspiration from the global bark and mulch industry, where operations are largely volume-based. Similarly in the mining industry, the team wanted to bring data that delivers efficiency and productivity improvements at operations.

With CVS, operators gain an understanding of their material flow on conveyor belts, including what’s passing through the belt every minute or every hour, how much is required to fulfil the target in one shift, and whether target ore processed has been achieved.

Each of these can be converted into tonnes per hour and tracked over time as needed.

“We felt that the other conveyor belt scanning products that we see around weren’t that easy to use, and they didn’t give you a nice user-friendly experience,” West says.

So the team focused on making the CVS as easy as possible to use. Loadscan listened to the market and identified their problems, and designed CVS to be a product that, when set up, works.

“All complication of software is hidden under the hood,” West says. “The interface is the part that users shouldn’t need to be an expert to use. The CVS has got to be intuitive.

“It’s got its own operator console – an onboard computer that comes standard with Wi-Fi antenna. It’s touch screen, it’s interactive, it’s easy to use.

“It’s also got its own web browser built into the computer, so all you need to do is connect the scanner via the Wi-Fi on your smart phone, tablet, or laptop, and you’ll be able to access the webpage for direct access to data.”

Loadscan’s CVS can also fit on conveyor belts ranging from a 400-millimetre to two-metre width.

“Because we developed the original trucking system for our construction business, we got to test it in real life and understand what’s required of the system. That helps us understand what the market wants,” West concludes

Find out more information on Loadscan’s CVS.

Find out more information on Loadscan’s LVS.