How volume scanning reshapes customer relationships Tracking material volumes across multiple sites is a [...]

Accurate, accountable, and profitable: How The Kearney Companies gains with Loadscan

Project Details

| CATEGORY: | Civil Construction Site development: clearing, earthworks, pipe and roads |

| LOCATION: | Riverview, Florida, USA |

| PRODUCT: | LVS-3TMM Mobile |

| WEBSITE: | thekearneycompanies.com |

On large-scale site development projects, accuracy isn’t optional – it’s essential. For Alan Payne, project lead at The Kearney Companies, based in Riverview, Florida, the difference between guessing and knowing has had a major financial and operational impact. After nearly four decades with the company, Alan has seen plenty of industry change, but few innovations have delivered as much value as Loadscan’s Load Volume Scanner (LVS) system.

A growing need for volume accuracy

Founded by Wes Kearney in 1956 with just a single bulldozer, The Kearney Companies has grown into one of West Central Florida’s leading site development contractors, employing more than 400 people and handling a wide range of subdivision, apartment complex, and commercial developments. With every project, a major part of the operation comes down to one thing: dirt—buying it, selling it, moving it, and measuring it.

Historically, fill material has been purchased by the cubic yard, but without a reliable volumetric measurement system in place, Alan recalls the company being routinely shortchanged.

“Before we were getting ripped off so bad; we were paying for 18 yards, which is just a guess,” he explains. “And we discovered through trial and error, when loads looked light, by levelling them and measuring the truck body to see the volume, we were getting between 12 and 15 yards.” “We figured there had to be a better solution than that because we were getting ripped off big time.”

The turning point came with the introduction of Loadscan’s LVS-3TMM Load Volume Scanners, which provide a precise volumetric measurement of every truckload through its LiDAR laser-based scanners. “So, we found that the Loadscan was what we’re looking for,” Alan says. “We had seen them around and we knew of them and what they did.”

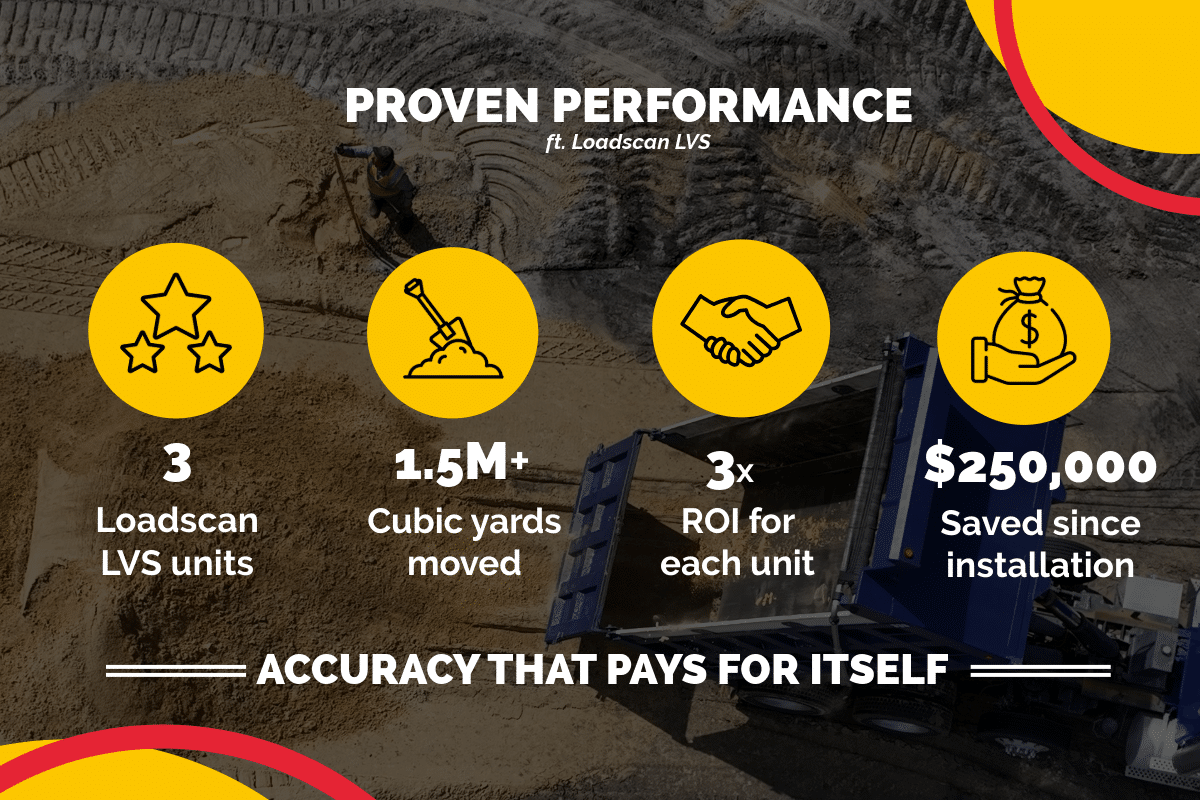

Today, Kearney Companies operates three of these trailer-mounted units across various jobs sites, dirt pits and other locations.

Fair pay and confidence in every load

The LVS system has changed the game by shifting pay-for-load guesswork into data-driven accuracy, which can then be used to avoid difficult conversations with pit owners or other suppliers.

“The critical thing is we’re now paying for what we get, averaging about 16.5 yards per truck, which is pretty close to the legal weight for most trucks,” Alan says.

This clarity in measurement has also eliminated long-standing disputes with suppliers. With ticket-based systems, disputes over truck volumes were common and often difficult to resolve. But with Loadscan, the data is irrefutable.

“Any dispute would be with a supplier of the material, but now there’s no dispute with them because we’re paying them for exactly what we’re getting. “If they don’t have their own volumetric scanner, we have an agreement in place that we’ll send the vendor a report the next morning for the day before, of all the loads that we hauled from their location,” Alan says. “The vendor checks the number of load tickets they provided to our trucks for that day against the number of loads we received on the dump end. “If a load or two didn’t get scanned, we’ll tell them what the average is for the day, and they’ll bill us those extra loads at the daily average.”

The scanner also gets used internally on jobs where material is being moved within a job site. In these cases, it’s not about verifying deliveries, it’s about checking the performance of Kearney’s own loader operators.

“We’ll set the scanner up when we’re moving material on site with dump trucks, just to make sure that our loader operators are loading a full 18 yards”, he says.

“Weight doesn’t matter on a job site with dump trucks, and we want to make sure that our loader operators are loading correctly, so we’ll just have the scanner on site where we’re monitoring our own loader operators.”

Massive return on investment

The financial impact of adopting Loadscan has been undeniable. Alan estimates each scanner has scanned an average of 500,000yd³, and he points out that if the company had continued paying for 18yd³ per load (instead of the measured 16.5yd³), they’d have overpaid by around 50,000yd³ per scanner. “At five dollars per yard, that’s a $250,000 difference,” he says. “So, each scanner has paid for itself at least three times over.”

But the return isn’t just financial — it’s operational. The scanners allow Kearney to optimise haul schedules, eliminate unnecessary loads, and streamline project billing. What once involved levelling truck loads manually or performing rough measurements is now handled automatically, consistently, and accurately.

Strong service and seamless integration

Alan describes the LVS system as straightforward, reliable and simple to use. “We’ve had no real issues but, when we’ve needed support, the local dealer here in Florida has been fantastic.”

He also notes that even Loadscan’s New Zealand-based support team is responsive, despite the time difference. “Even if we have to reach out overseas to New Zealand, their response has been almost immediate.”

Building trust with clients and suppliers

One of the most significant outcomes of adopting LVS technology has been the increased trust and collaboration between The Kearney Companies and its suppliers, and even with its clients. In several cases, project owners have opted to use Kearney’s scan data to validate the quantity of material delivered and placed, knowing it reflects true volumes, not ticket-based estimates.

“One of the interesting things that’s happened, is that some of our clients will now ask us to bill them for the fill material and placement off our daily Load Scanner volumes, because they know that they were not getting what they were paying for before,” Alan says.

“We’ve done jobs where we’ll put the Load Scanner on site, and we’ll give our client a report every day of how many yards were hauled in there, and they will pay us for the material and the placing off that Loadscan quantity.”

Practical, versatile, and proven

The flexibility of the Loadscan system means it’s used in a variety of ways across Kearney’s operations—from verifying third-party deliveries to auditing internal performance. In one example, Alan describes how Kearney’s in-house mulch production, made from chipped trees, is also measured with LVS before resale to manufacturers.

Whether buying, selling, or simply moving material, the scanner ensures that everyone knows exactly what’s in the truck. “It’s not a guessing game anymore,” he says. “You pay for what you get and, if you’re on the selling side, you can show your customer that they’re getting what they’ve paid for.”

A smarter way to do business

Alan says the adoption of Loadscan’s Load Volume Scanners has not only considerably reduced waste and improved billing accuracy, it has fundamentally changed the way The Kearney Companies thinks about material movement. “Before Loadscan, it was always a guessing game,” Alan says. “Now, we’re not guessing. We’re managing. We’re measuring. And we’re making better decisions every day because of it.”

With three scanners in operation and over 1.5 million cubic yards measured to date, The Kearney Companies has no intention of going back to the old ways of doing things. And with results like these, it’s easy to see why.