Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

What is load volume scanning?

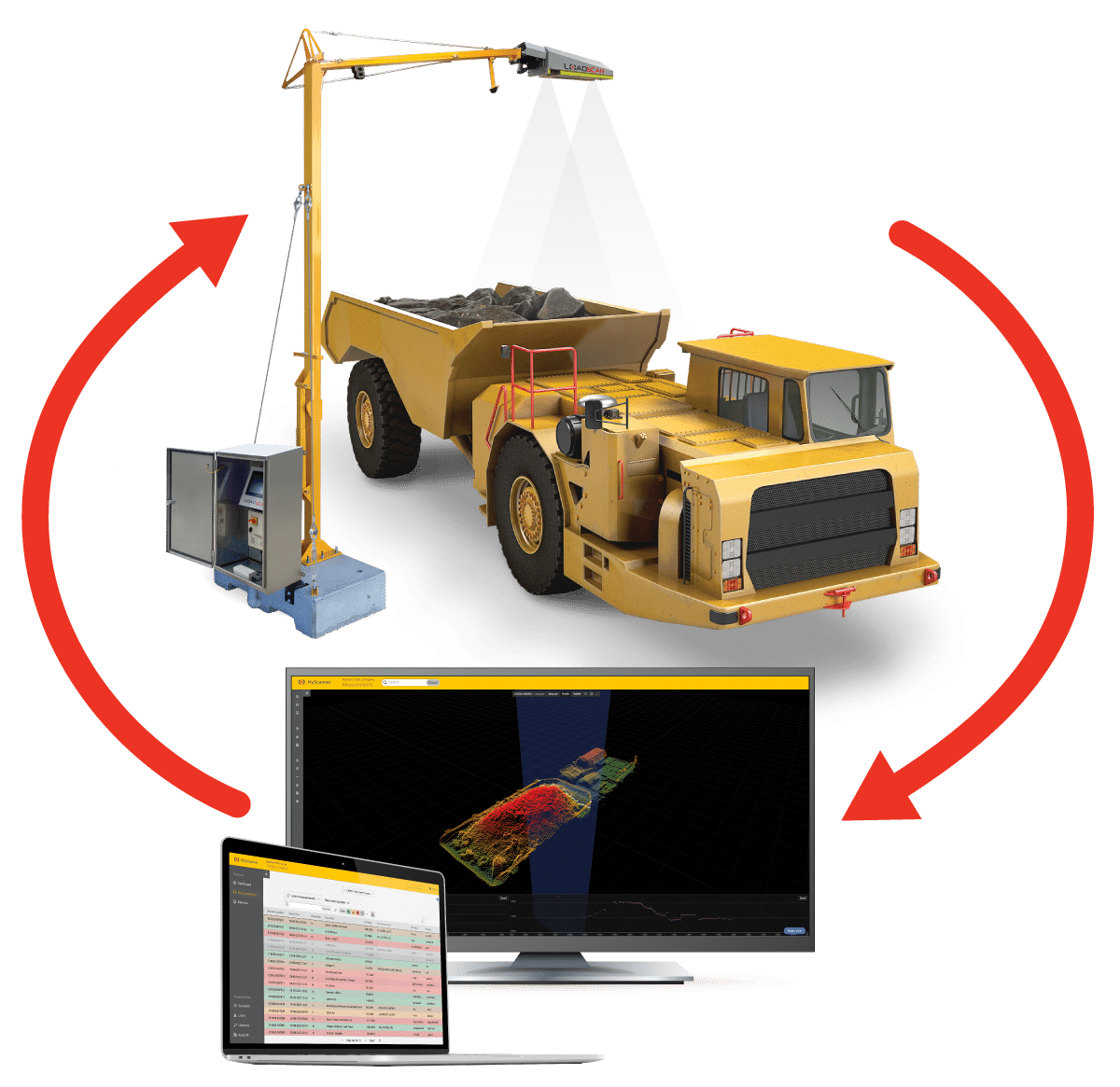

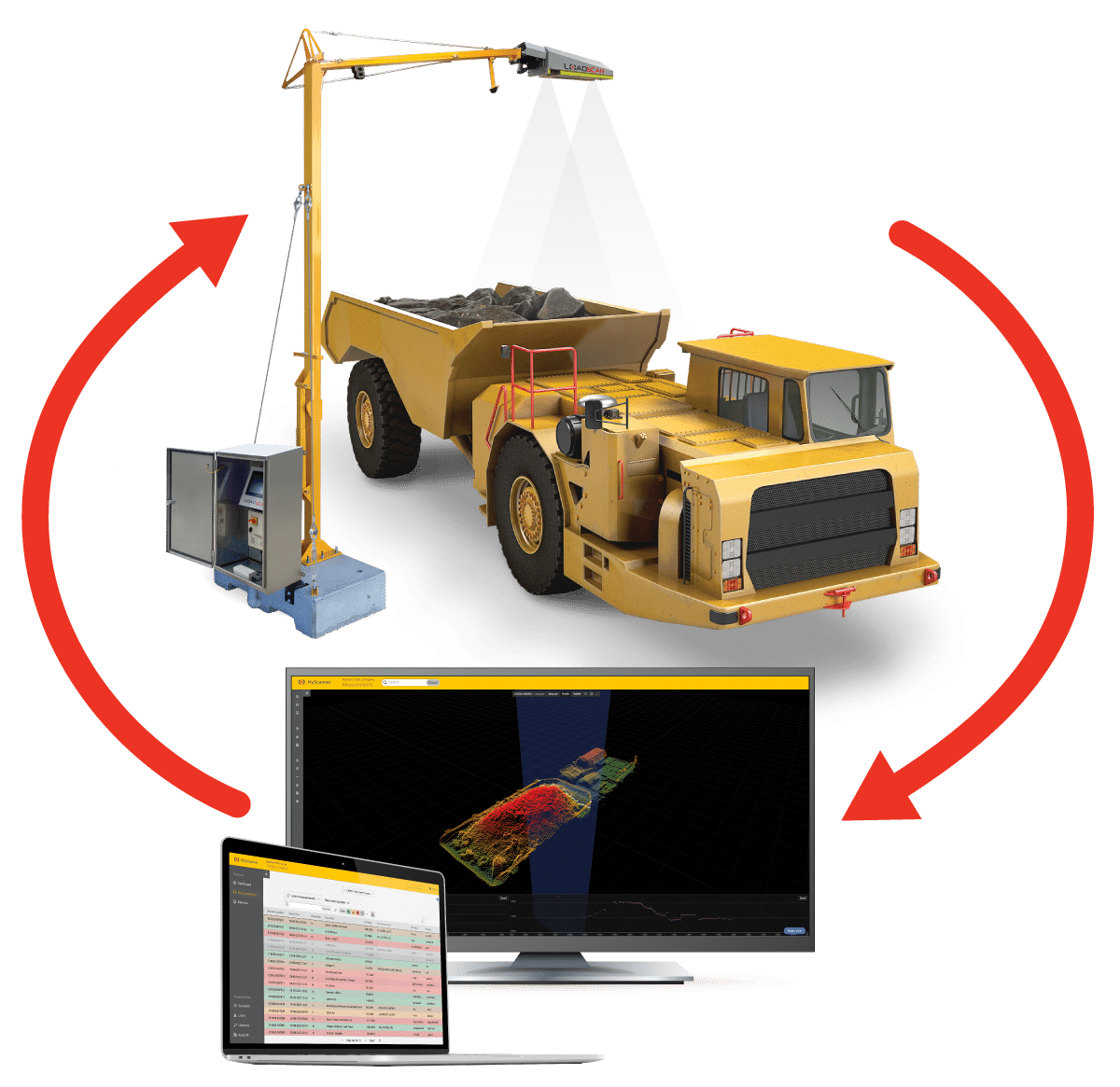

Loadscan is at the forefront of mining tech! The Mine Payload Scanner (MPS) system utilizes eye-safe Lidar laser scanning technology combined with proprietary Loadscan software to measure the exact volume of material loaded into a truck bin. With the MPS system you’ll measure actual volume, not a converted weight estimate.

By accurately calculating net volumes delivered for processing you can eliminate arguments over tons delivered by the haulage contractor or haulage department to the mill. It also enables you to optimize loading for maximum asset utilization.

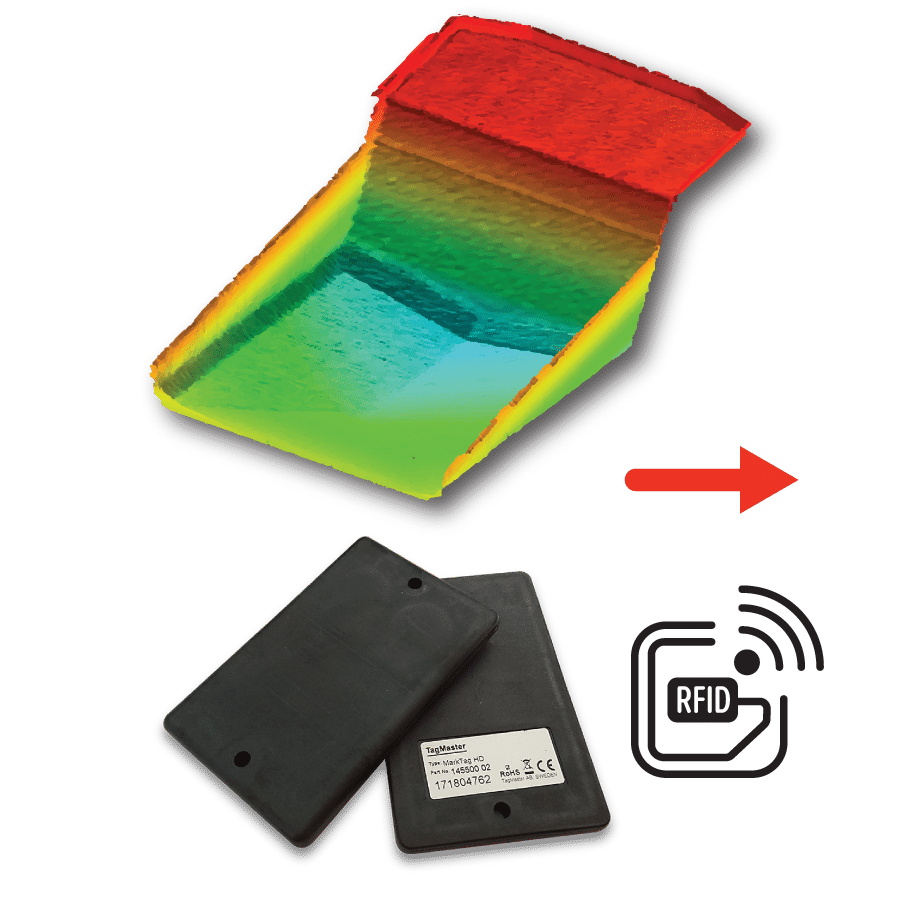

A 3D scan image of every load is generated, providing an audit trail and visual record of loading. Customers have found this extremely helpful when training and coaching their operators.

How the MPS system works

Empty truck is scanned to create reference scan in the database

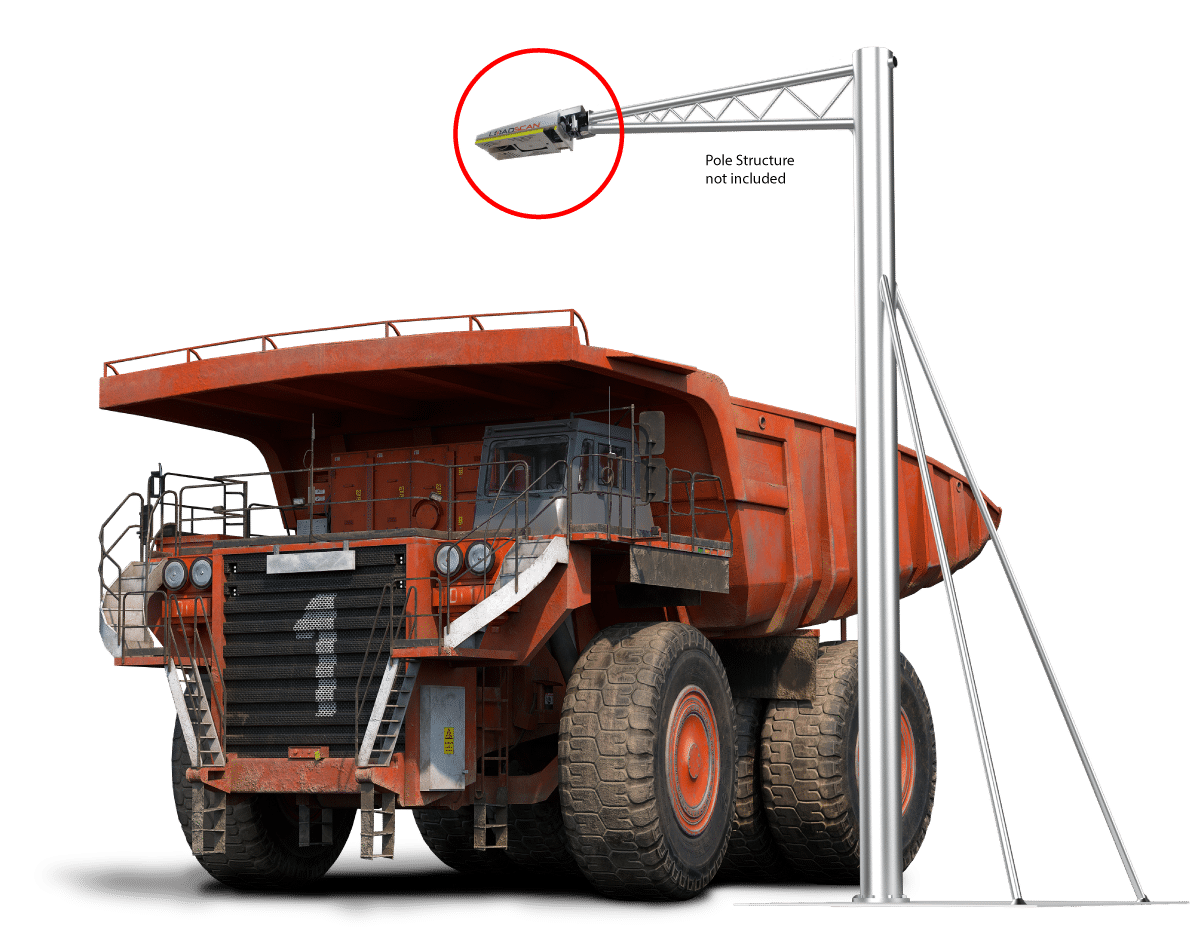

Trucks are scanned by driving below an elevated scan head, which can be mounted on a pole, gantry, or underground mine portal. The scanning process is fully automated.

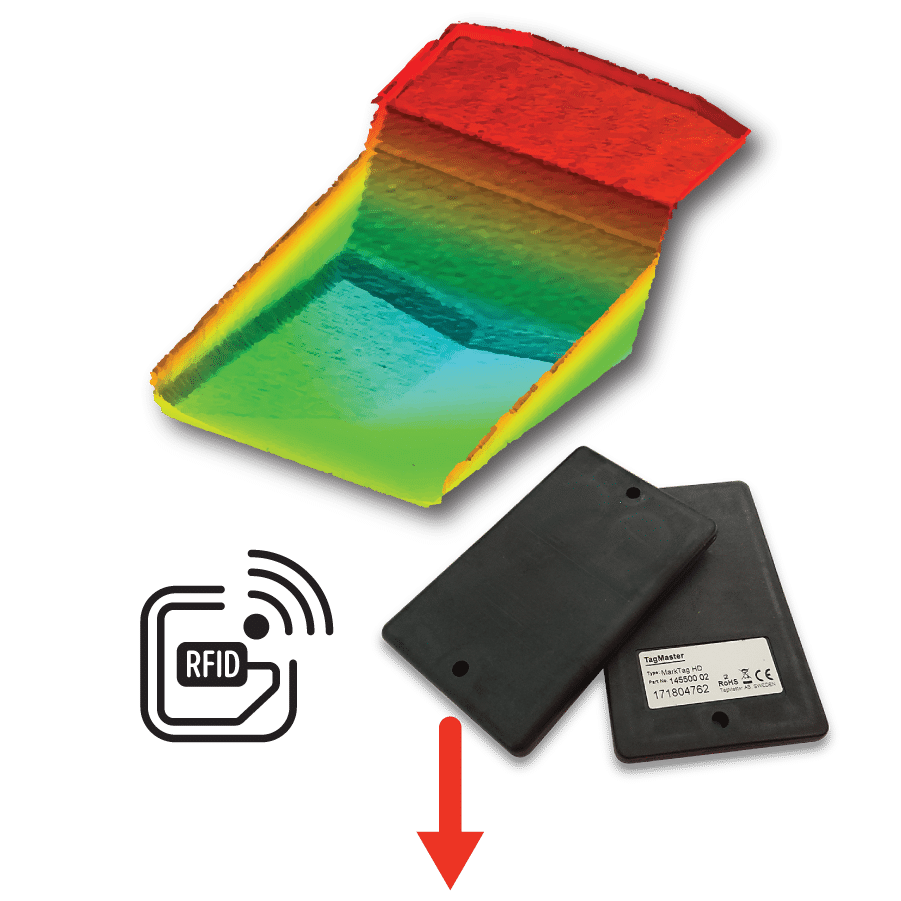

Trucks can be tracked manually or fitted with RFID tags for automatic identification

Proprietary MyScanner™ software reports volumetric measurement, including 3D load profiles of every load

How the MPS system works

Empty truck is scanned to create reference scan in the database

Trucks can be tracked manually or fitted with RFID tags for automatic identification

Trucks are scanned by driving below an elevated scan head, which can be mounted on a pole, gantry, or underground mine portal. The scanning process is fully automated.

Proprietary MyScanner™ software reports volumetric measurement, including 3D load profiles of every load

Loadscan is the only load volume scanning company worldwide to have achieved trade certification approval for truck volume measurement. Our LVS-3 system is certified for trade in New Zealand under Trade Approval Certificate 1556 (MAPPS NZ), pattern approval Certificate 13/1/15 (NMI AUS) and the National Type Evaluation Program Certificate of Conformance 24-001P for weighing and measuring devices (NTEP USA). The MPS shares a common scan engine and measurement algorithms with the LVS and delivers the same level of accuracy. The MPS is sold as ‘Monitor Only’ and ‘Not Legal for Trade Use’, however it will still perform to the same high level of accuracy as required by the Trade certificates in New Zealand and Australia.