Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

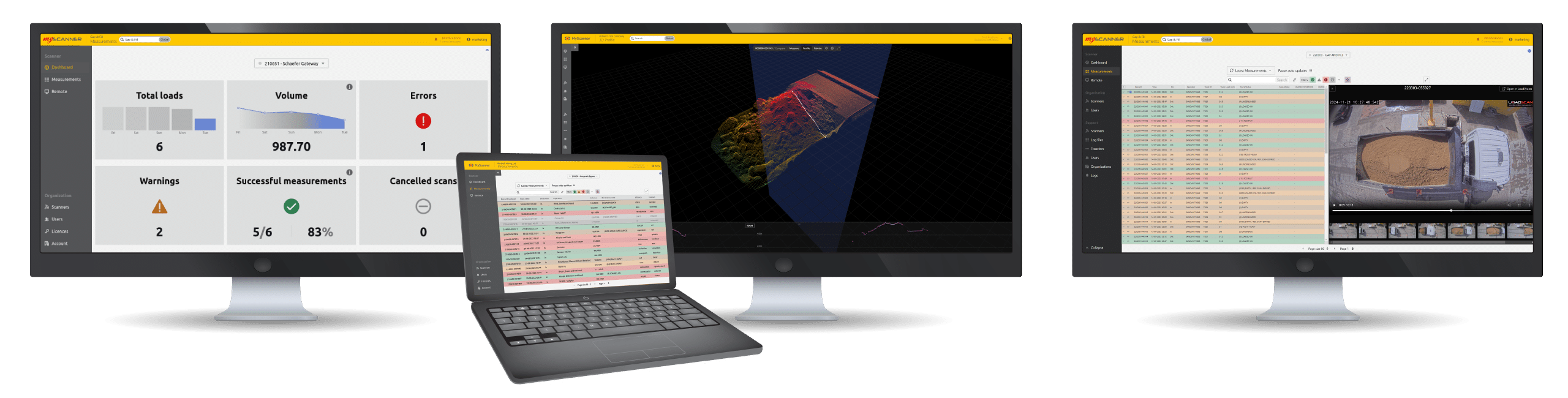

MyScanner™ Cloud Service

MyScanner™ is a secure web portal allowing remote access to your scanner, real-time presentation of scan data and access to support from anywhere in the world.

Remote Access Anytime:

Your data security is important to us. MyScanner™ uses industry standard AES-256 encryption security to ensure that all stored data and user accounts are completely secure and protected. Data connections are also fully secured with modern Transport Layer Security (TLS) and follow industry best practice

Standard Features

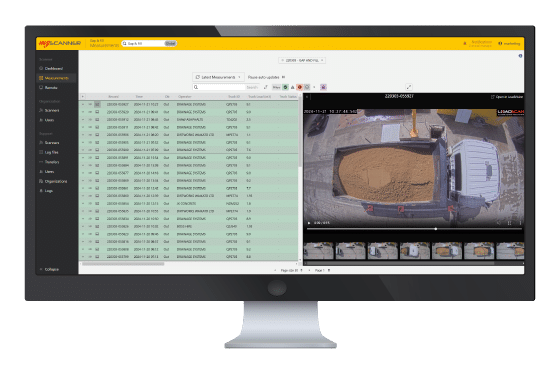

Measurements Page

The measurements page shows all the scans that have gone through the scanner detailing the time, direction, operator, truck ID, truck and trailer load measurement and product. From this page, you can also access the 3D Load Profiler for a visual breakdown of each scanned load.

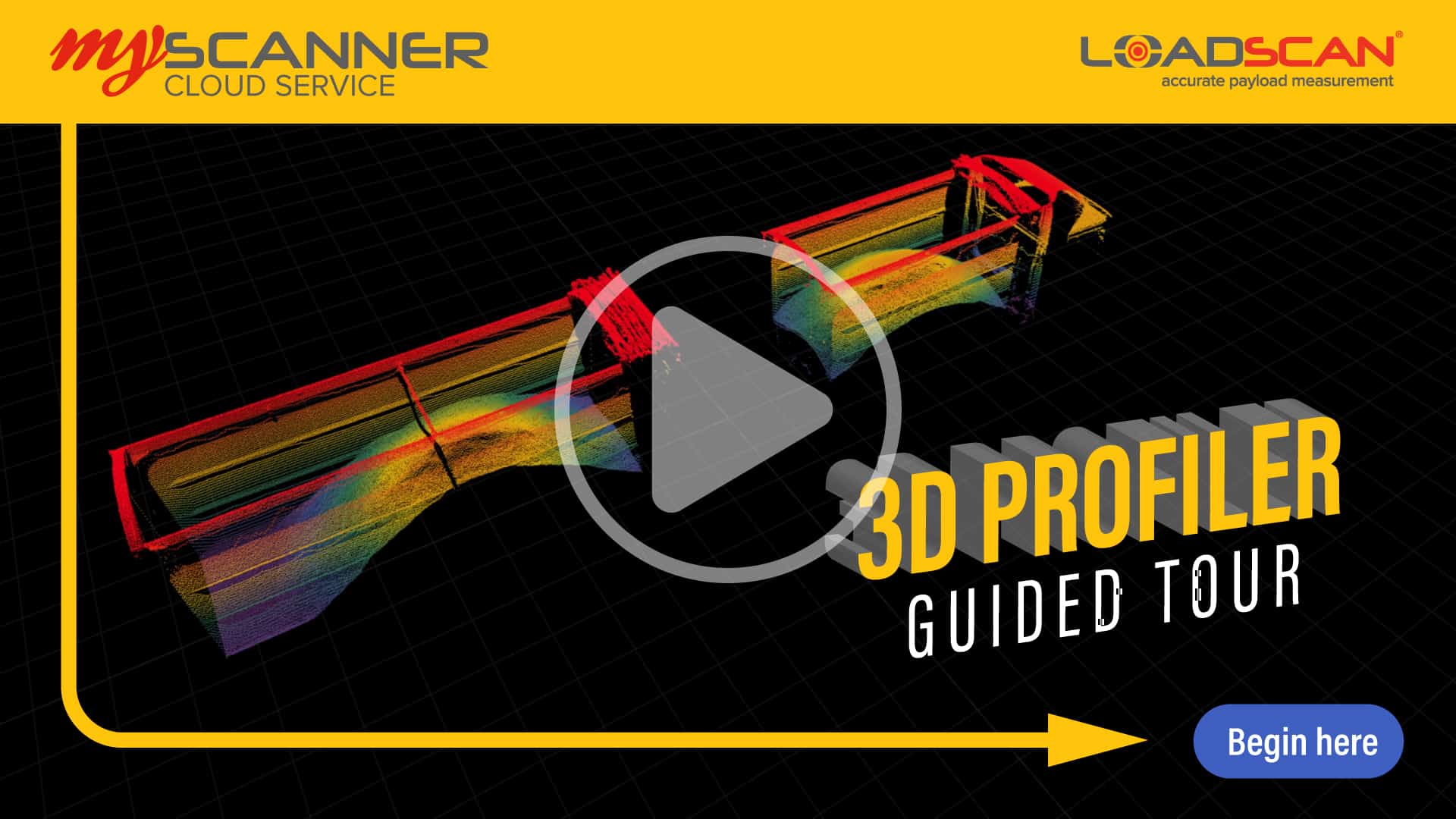

3D Load Profiler Graphics

The Loadscan’s 3D Load Profiler gives a graphical load representation for visual load shape and distribution feedback. Allows operators to detect off-center or unsafe loading, load fragmentation and general load shape.

Print Measurement Record Tickets

You can print measurement record tickets directly through MyScanner, offering a streamlined and consistent documentation process. These tickets mimic the familiar LVS format, ensuring clarity and compatibility.

Automatic Payments and Subscriptions

MyScanner makes billing easy with automatic payments through Stripe, a secure and trusted platform. You can pay by credit card or direct bank transfer, so your subscription renews smoothly without the need for manual intervention.

Additional Features*

Load Distribution Analysis

How a load is distributed in a truck tray affects loading efficiency, tire wear, machine stress, and safety. Avoid costly blowouts and protect equipment by ensuring proper load placement. Loadscan shows left/right and front/rear distribution using center-of-mass, heap slope angles, and load shape data.*

Blast Fragmentation Monitoring

The distribution of rock fragment sizes (fragmentation) after blasting affects digability and truck loading efficiency, impacting productivity. The fragmentation within a truck load can be estimated from the 3D texture of the load’s surface and reported for blast performance monitoring and optimization.*

Fill Factor Calculation

Loading trucks to capacity without over-loading is important for maximum productivity. Truck fill factor is a measure of how well a truck body is utilized. This can be computed from measured load volume, tray shape and size, load profile, fragmentation and optionally, externally supplied weight data. *

Rock-Fall Risk Identification

Visual highlighting of truck tray edge regions where the load is at risk of falling off the side, with configurable alarm thresholds allows operators to identify unsafe loads. *

MyScanner™ Add-Ons*

†LoadVision add-on

The LoadVision add-on takes your Loadscan Load Volume Scanner to the next level by providing clear, visual insights into your scan and measurement records. With LoadVision, you can now easily view video footage and snapshot images of both empty and loaded truck loads directly through the MyScanner measurements page.

With LoadVision, you get more than just data—you get the full picture, empowering you to improve efficiency, transparency, and accuracy across your operations.

The LoadVision annual subscription involves a one-time capital purchase for the hardware, along with an annual subscription for access to MyScanner

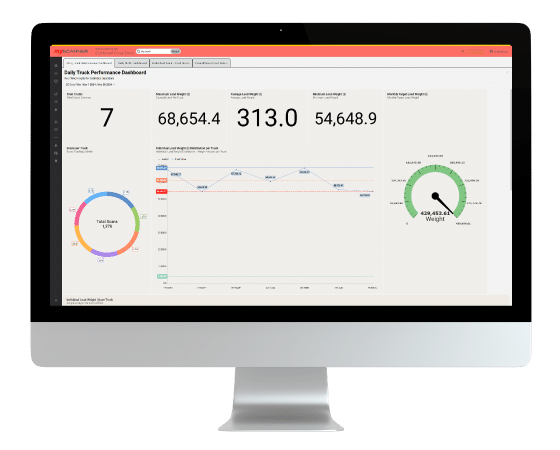

†MyScanner Analytics add-on

Unlock the full potential of your measurement data with the MyScanner Analytics add-on. Seamlessly consolidate and report on data from all scanners across your organization. Create easy-to-use dashboards with clear, visual charts and graphs. Quickly track key metrics like truck performance, load counts, and target volumes to help improve your operations.

Create easy-to-use dashboards with clear, visual charts and graphs. Quickly track key metrics like truck performance, load counts, and target volumes to help improve your operations.

You can use ready-made dashboards or customize them with filters and edits to suit your needs. It’s also easy to export your dashboards to PDF, PowerPoint, or Excel for sharing and reporting.

The MyScanner Analytics Add-On is available at an additional cost to your standard annual MyScanner Licence.