Loadscan expands to Brazil with new branch Belo Horizonte, Brazil – Loadscan, the global [...]

Conveyor Volume Scanner (CVS)

Real-time access to live production data

Manage and optimize material flow with the mine-specific Conveyor Volume Scanner (CVS). It’s a viable measurement alternative to traditional weight-based systems and, with a measurement accuracy better than 98.5%, the CVS enables accurate real-time inventory tracking and reporting.

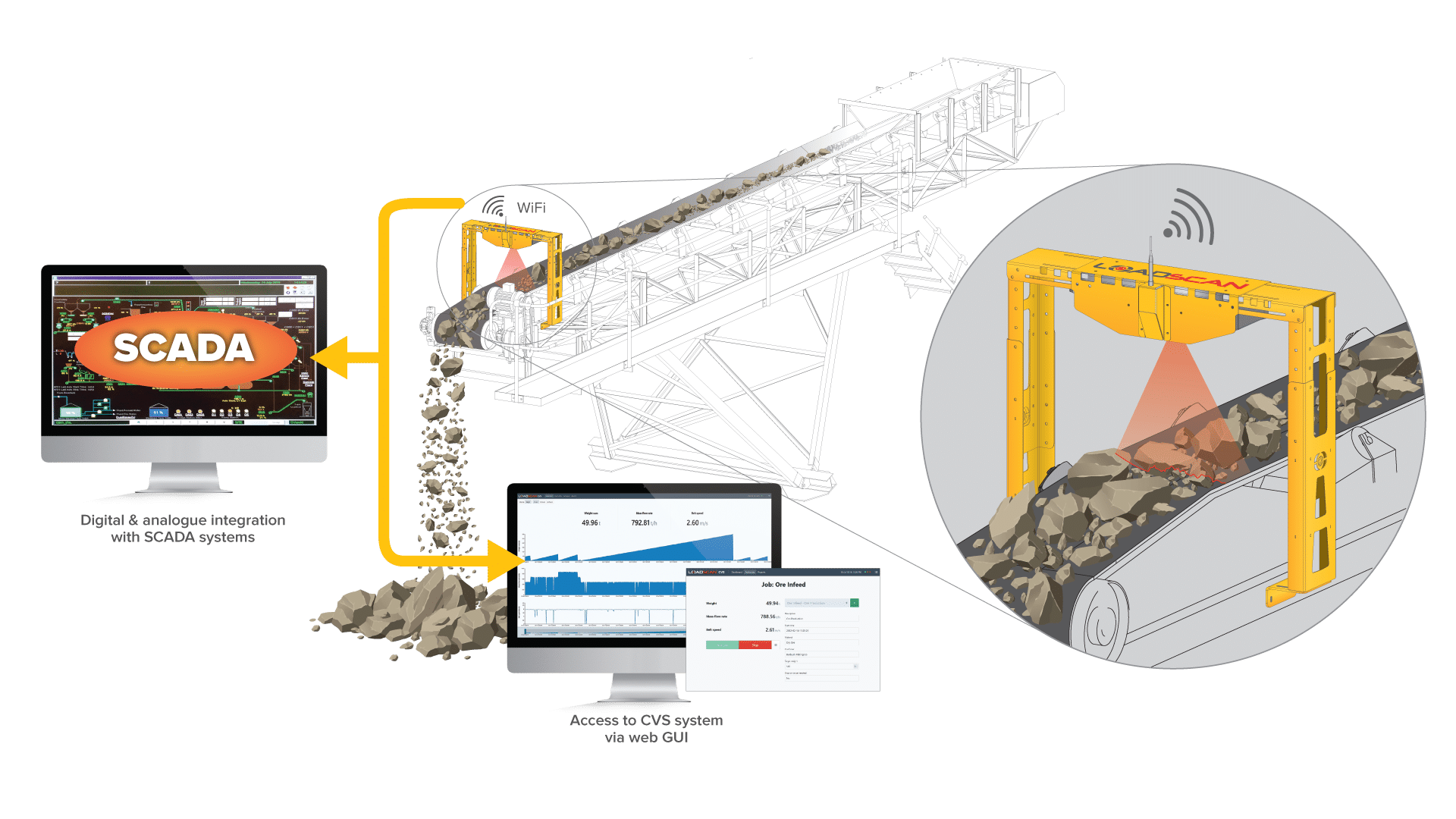

A proximity sensor ensures reliable non-contact speed measurement, eliminating the need for regular and costly recalibration. Real-time access to live production data is available with digital and analogue integration into most mine management and SCADA systems. Built-in 2.4 or 5 GHz WiFi allows password-secured remote access via tablet, smartphone, laptop or company network.

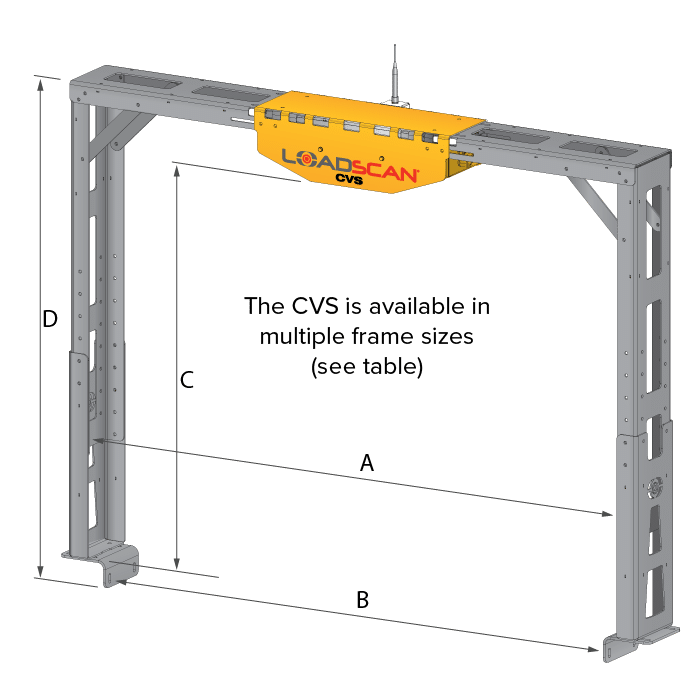

Available in three sizes, the CVS mining conveyor scanner can be adjusted to mount easily on a variety of belt sizes, providing maximum flexibility to suit your conveyor system. The user-friendly operator interface ensures simple implementation and delivers powerful operational reporting.

If you want to more effectively understand your production flow rate, the CVS is the perfect solution.

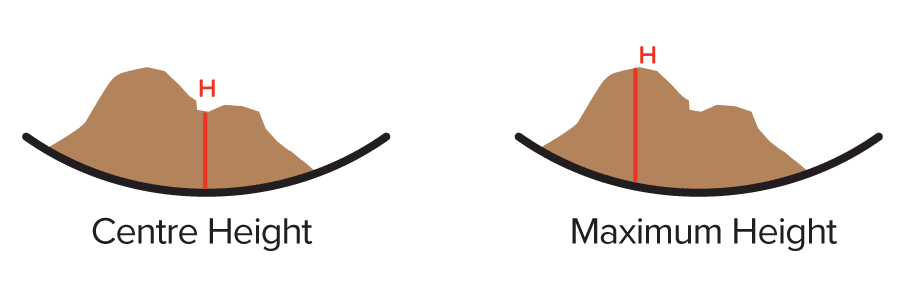

Load height measurement output

Identify large rocks and monitor load height on the belt (height/depth of the load material above the belt). Two measurement methods are supported:

Live production data at your fingertips

With digital data input and output to external mine management or SCADA/PLC systems, the CVS allows for real-time inventory tracking and reporting. The system includes onboard Modbus TCP Server with full configuration interface, RESTful API option to communicate with external control systems, and an optional add-on I/O allowing external analogue (4-20mA) communication. Throughput can be tracked and reported by volume or weight*.

Benefits of conveyor volume scanning with the CVS

- Real-time access to live production data with digital and analogue integration into mine management and SCADA systems

- Manage and optimize material flow in real-time

- A viable measurement alternative to traditional weight-based systems

- Eliminates the need for regular and costly scale recalibration

- Better manage your equipment and accurately control your throughput

Key technical features

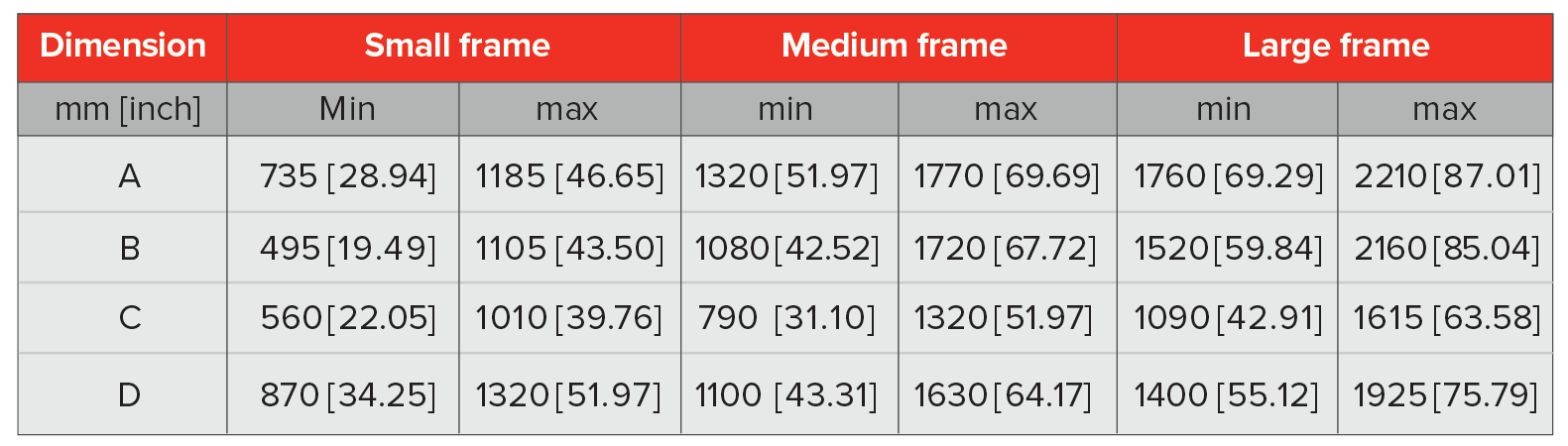

A range of frame sizes to fit most conveyor belts

In most cases your scan head will be attached to one of our expandable standard frames for a secure fit to your conveyor belt. The CVS system can be used with shallow and deep ‘V’ conveyor belt set-ups.

NOTE:

- Small, Medium and Large frame extenders can be interchanged to produce extra high or extra wide variations for large belts up to 3000mm (118in) wide.

- All frame sizes are available in a Wide Temperature Range option (-40C to 60C / -40F to 140F).