How volume scanning reshapes customer relationships Tracking material volumes across multiple sites is a [...]

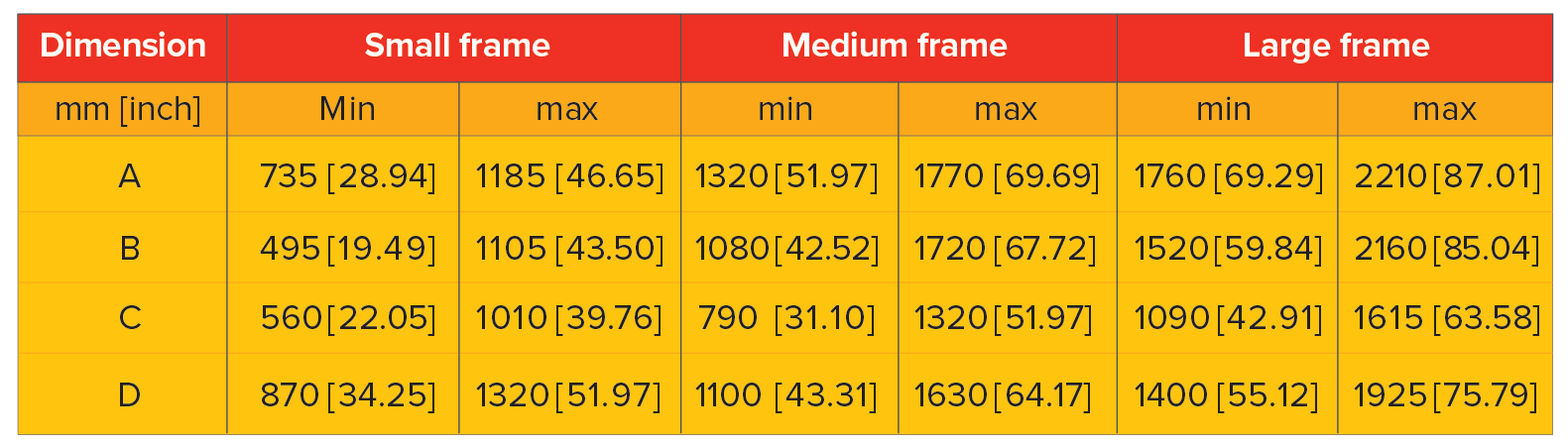

Conveyor Volume Scanner (CVS)

Enhanced production control and effective stockpile management

Loadscan’s Conveyor Volume Scanner (CVS) measures and reports on bulk flow to give you enhanced production control and effective stockpile management. It’s a viable measurement alternative to traditional weight-based systems and, with a measurement accuracy better than 98.5%, the CVS enables accurate, real-time inventory tracking and reporting.

The CVS provides highly accurate volume measurement, enabling you to set batching and job staging. It can be programmed to start job and stop belt when your target volume is reached, providing you with greater control over your production.

It’s a non-contact technology, eliminating the need for regular and costly recalibration. The system allows for external digital and analogue (4-20mA) input and output.

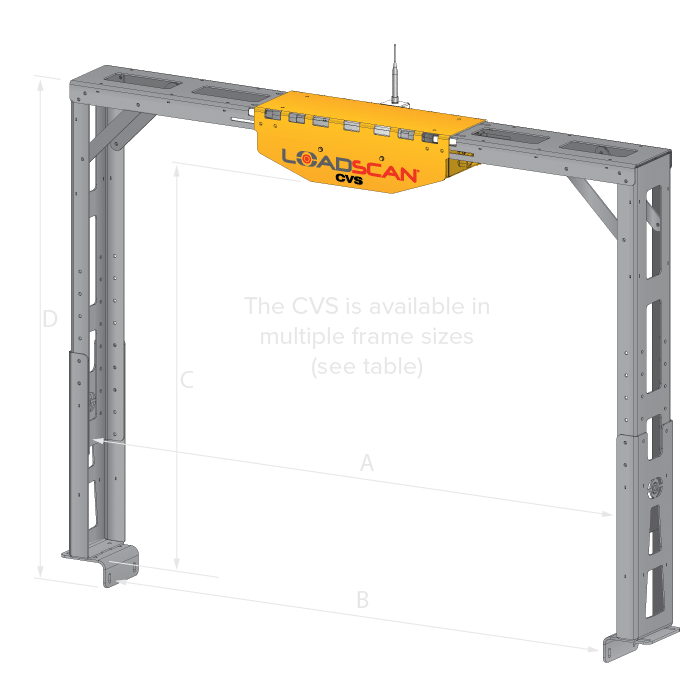

Available in three sizes, the CVS conveyor scanner can be adjusted to mount easily on a variety of belt sizes, providing maximum flexibility to suit your conveyor system. The user-friendly operator interface ensures simple implementation and delivers powerful operational reporting.

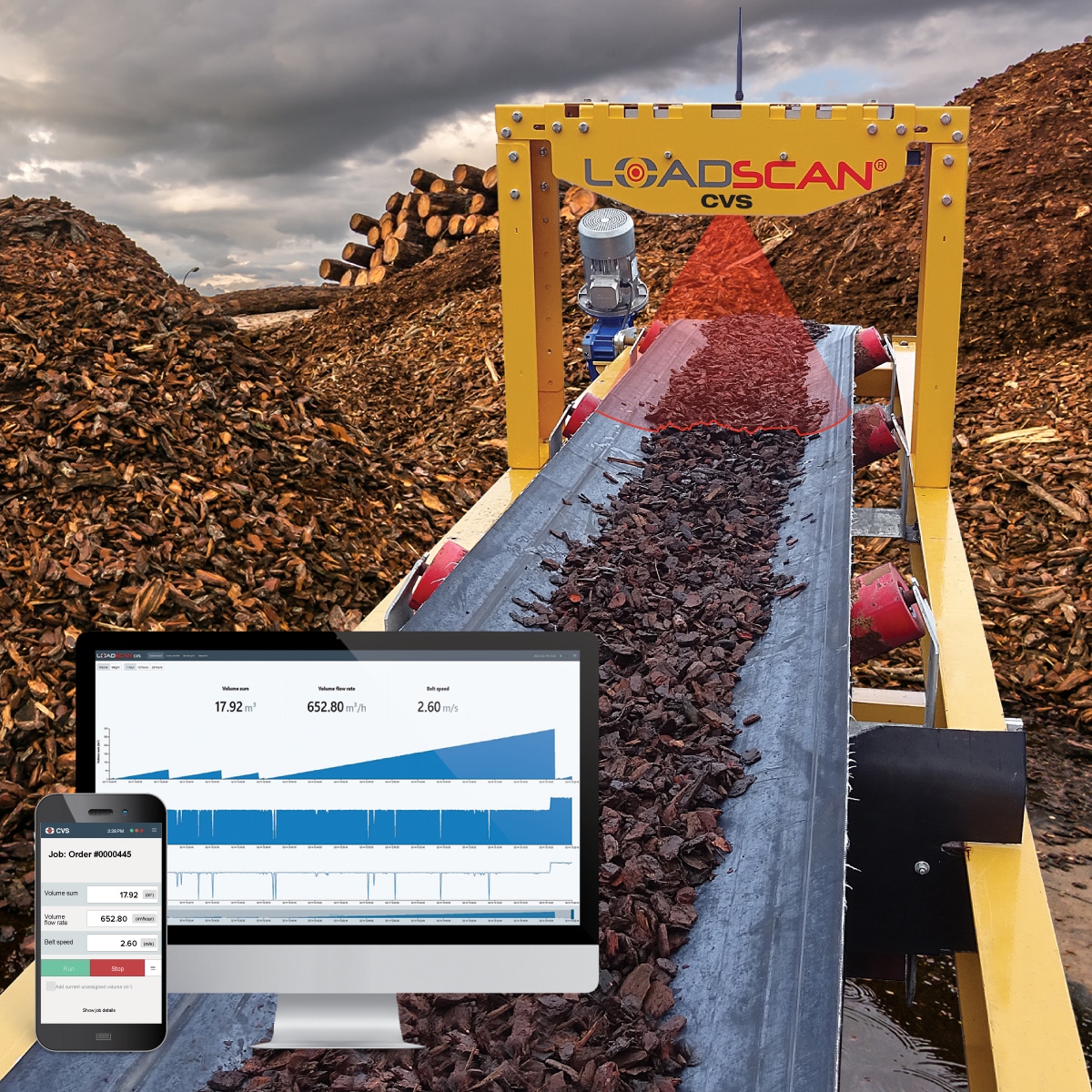

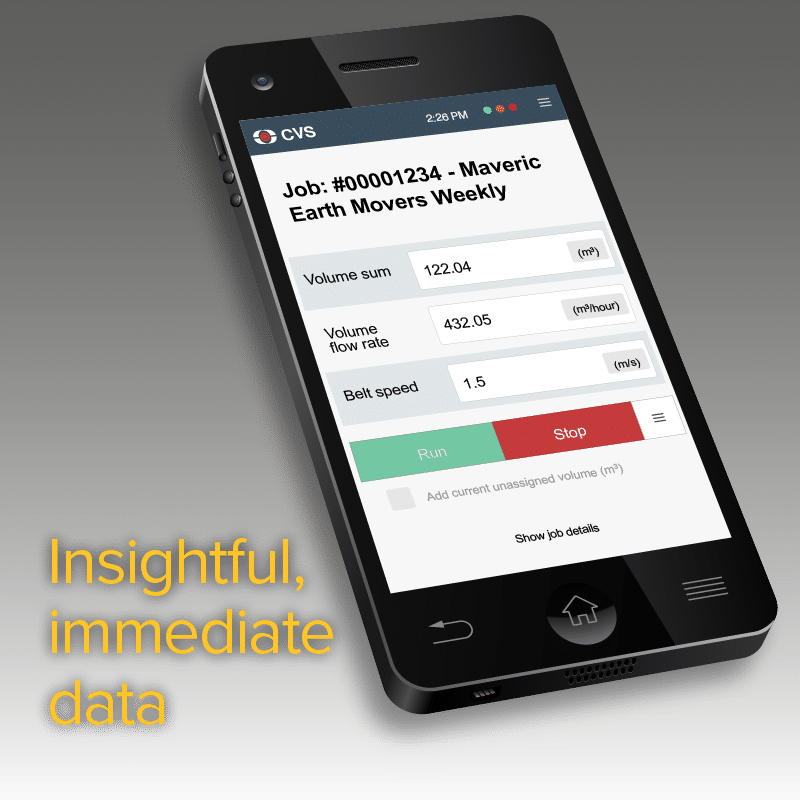

The CVS allows you to monitor and operate your conveyor belt on the fly, enabling better decision-making based on accurate, real-time data feeds.

Unlike other optical belt scales, which provide some data but don’t integrate easily, the CVS web-based user interface has been developed in conjunction with industry to ensure it’s hassle-free and data-rich.

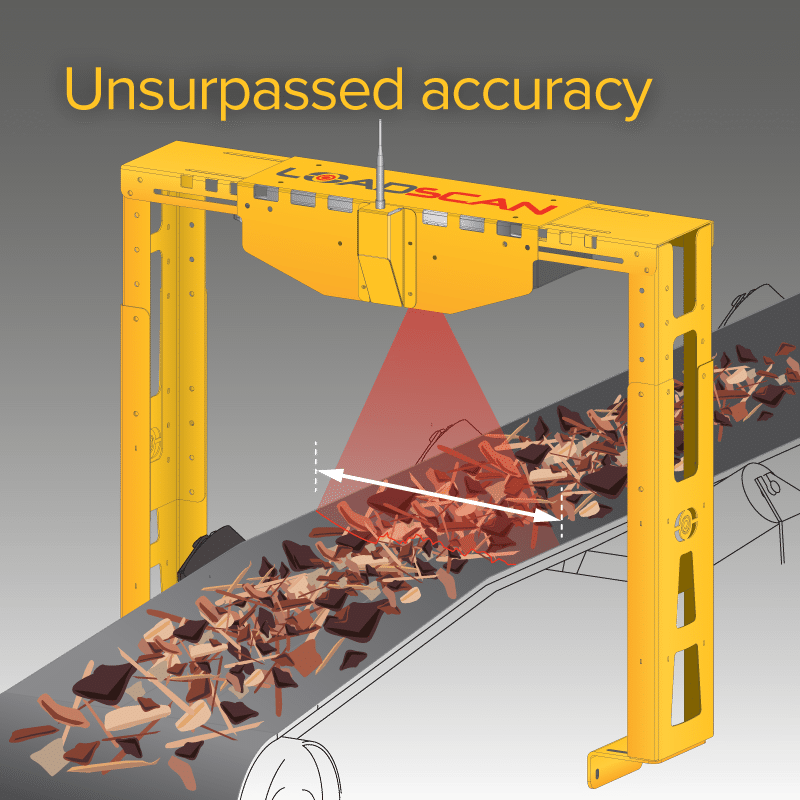

Your single laser continuously scans the full width of your (some other scanners measure a limited number of fixed positions across the belt) so you know exactly what’s flowing by and can optimise your production rates.

The CVS records detailed bulk flow measurement and supplies you with the right information wherever you need it (in the palm of your hand or in the back office) so you can monitor and manage your conveyor belt’s usage and productivity in real-time.

Benefits of conveyor volume scanning with the CVS

Key technical features

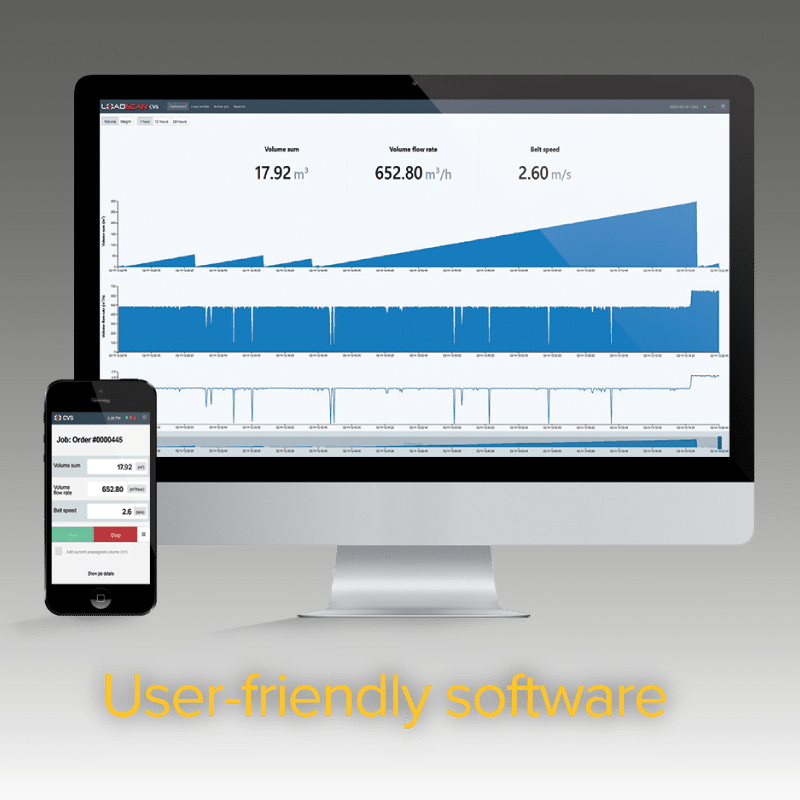

A range of frame sizes to fit most conveyor belts

In most cases your scan head will be attached to one of our expandable standard frames for a secure fit to your conveyor belt. The CVS system can be used with shallow and deep ‘V’ conveyor belt set-ups.

NOTE:

- Small, Medium and Large frame extenders can be interchanged to produce extra high or extra wide variations for large belts up to 3000mm (118in) wide.

- All frame sizes are available in a Wide Temperature Range option (-40C to 60C / -40F to 140F).