How Loadscan takes the guesswork out of tricky materials When dealing with materials [...]

Large Rigid Dumpers Measured Accurately with Loadscan’s LVS

A common misconception is that Load Volume Scanner (LVS) systems are only suitable for road trucks or smaller articulated haulers. Loadscan has proven this wrong by providing accurate, low-maintenance payload measurement solutions for all truck types—including the largest rigid dumpers used in open-cut mining.

With this system, mine operators can gather detailed data, reduce reliance on on-board weighing systems, and optimise productivity—all from a single drive-through scan.

Portable and Low-Maintenance Alternative to On-Board Scales

Unlike on-board weighing systems, which require frequent calibration and ongoing maintenance, the LVS only requires a single installation. There’s no need for costly earthworks or a full fleet fit-out, and expensive fixed truck scales are unnecessary. A single Loadscan unit provides traceable in-motion payload measurement for all trucks that pass beneath it, including large rigid dumpers.

This approach not only reduces maintenance costs but also delivers real-time, actionable data for mine management.

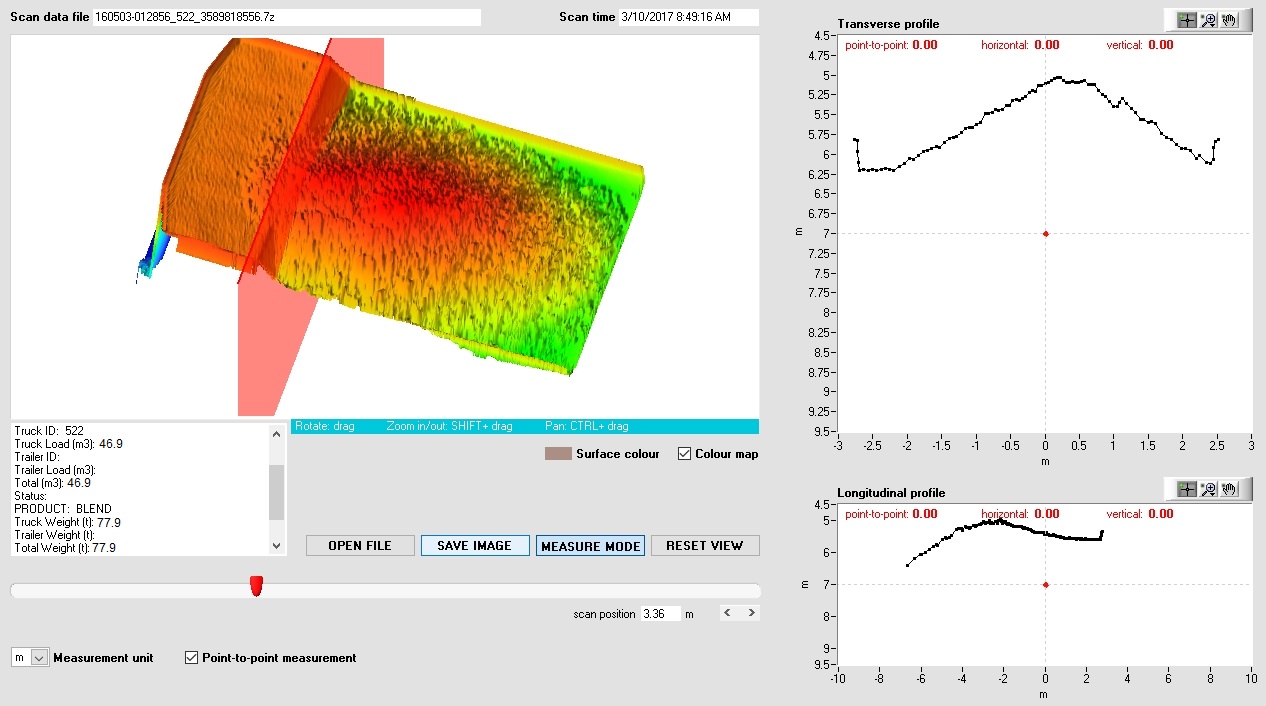

3D Load Profiling and Operator Training

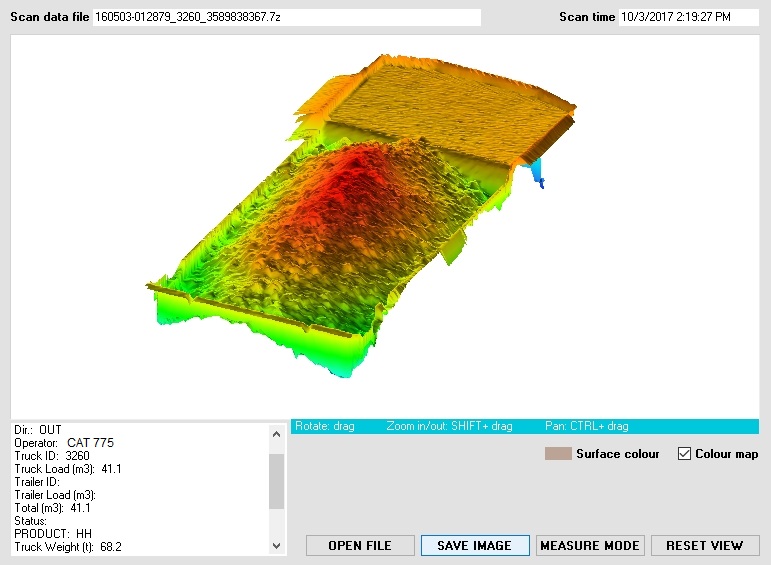

The LVS creates 3D visual profiles of each load, allowing operators to see exact load distribution. For example, in a trial with CAT 775 trucks, operators could identify which loads were larger or smaller, ensuring safe haul road conditions and reducing equipment wear.

RFID tags automatically identify each truck, and volume measurements are converted to metric tonnes using density factors. This provides a detailed picture of actual payload versus manufacturer-rated maximums, helping mines optimise load volumes and calculate precise cost per tonne.

Optimising Mine Productivity and Efficiency

By scanning trucks in-motion, mine teams gain insights into productivity, loading consistency, and haul road safety. The LVS integrates with office management systems, accounts for haul-back material, and produces real-time reports. This ensures that every large rigid dumper is loaded optimally and safely.

Mine operators benefit from:

Accurate payload measurement

Reduced on-board scale maintenance

Operator training through 3D load visualization

Optimised cost per tonne calculations

The Smart Solution for Large Rigid Dumpers

Loadscan’s LVS offers a comprehensive, low-maintenance solution for all dump truck types, including the largest rigid dumpers. With in-motion scanning, 3D load profiling, and office integration, mines can improve productivity, safety, and operational efficiency—all while reducing costs associated with traditional truck scales or on-board weighing systems.