How volume scanning reshapes customer relationships Tracking material volumes across multiple sites is a [...]

Delivering value beyond volume measurement

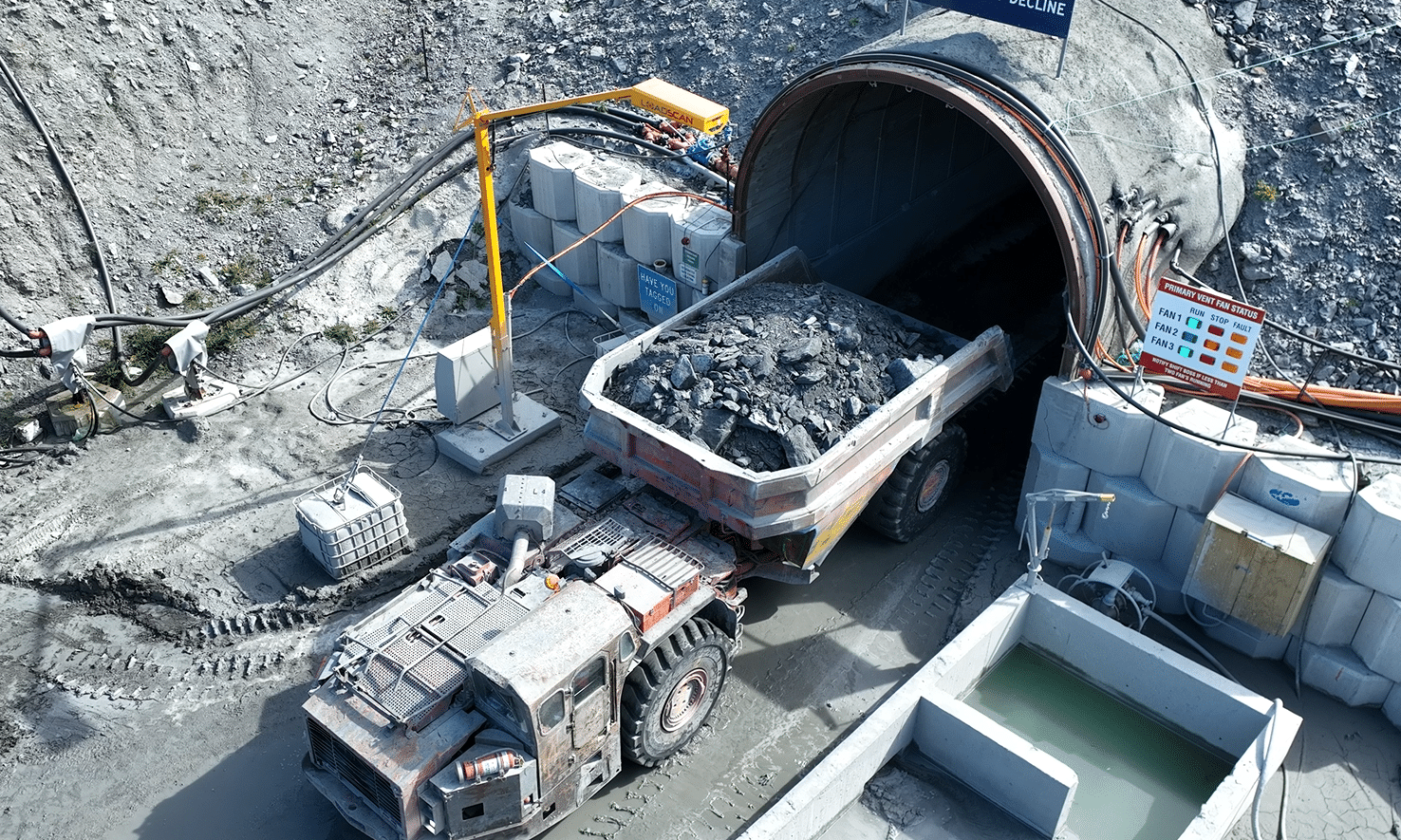

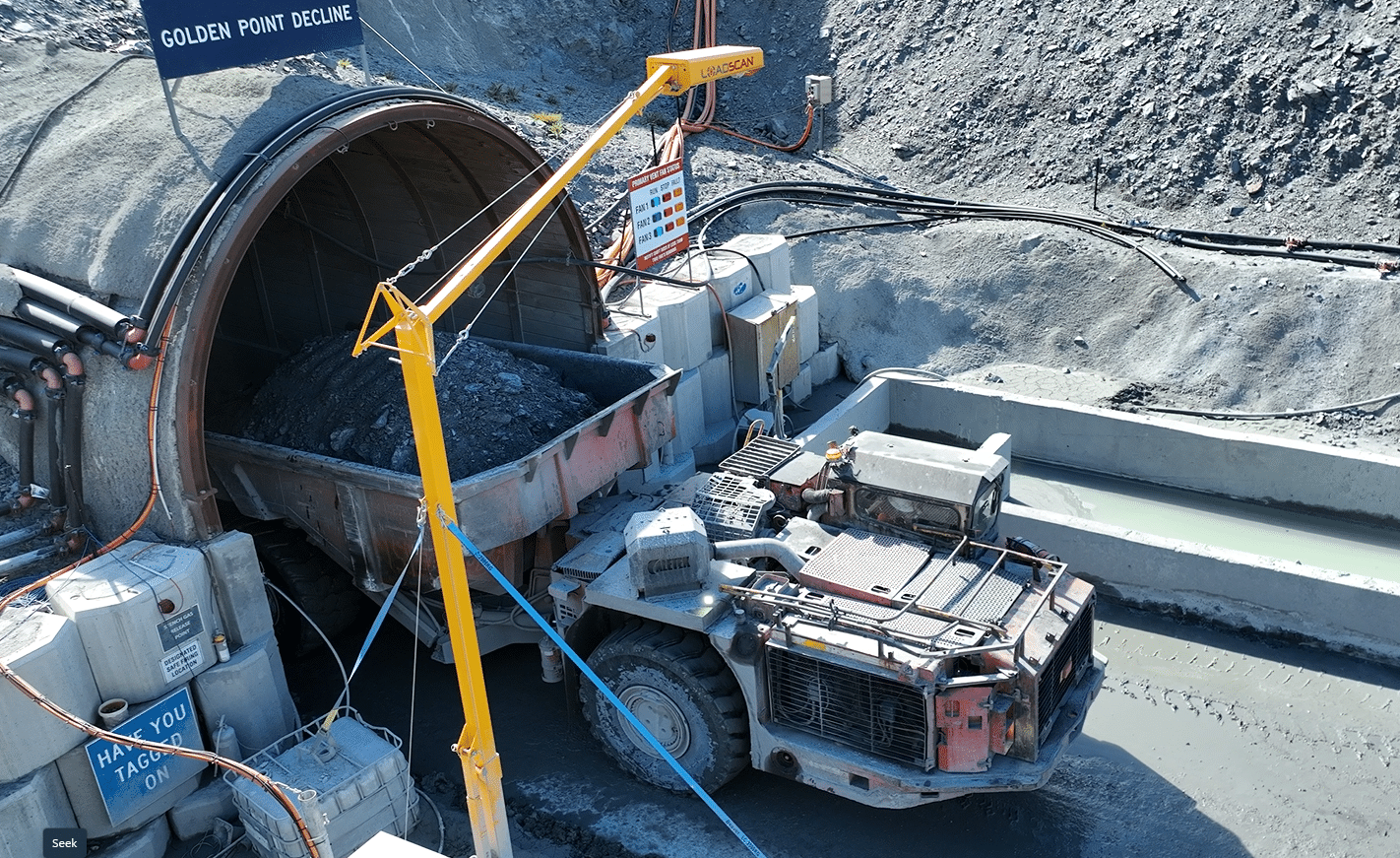

At Macraes Mine in Otago, the Loadscan Mine Payload Scanner (MPS) has evolved from a volume-tracking tool into a quiet powerhouse of operational insight. Senior Geologist Graham Gibson has watched the technology reshape how the team thinks about efficiency, not just in terms of tonnes moved, but in how every truck, operator, and load performs across the day.

Tackling carryback head-on

Carryback might seem like a small frustration, but at a mine of Macraes’ scale, even a modest amount of material left behind adds up fast. Lost payload, wasted fuel, disrupted haul cycles – it all bites into productivity. The MPS, Graham says, has become their early-warning system.

“I think that’s one of the main benefits for the Loadscan system is just any truck with carry back in it, it’s just getting it out straight away.”

A level pad beneath the scanner ensures every scan is consistent, helping the team spot issues long before they become costly patterns.

Seamless integration into daily workflow

What's made the biggest difference is how naturally the scanner fits into the fleet's daily rhythm. Drivers approach at a controlled speed, pass beneath the unit, and continue on – scanned, verified, and back to work without disruption. After tipping, another pass confirms whether any carryback remains.

"So they'll come up to the scanner, slow down, get an even scan, even speed all the way through…"

The result is a simple loop that quietly reinforces accuracy and discipline throughout the operation.

Beyond the surface: Data that drives efficiency

While the MPS was originally installed for load volume measurement, it has opened up far more possibilities. Graham notes how the data reveals loading patterns that would otherwise go unseen. These are issues like uneven distribution, off-centre loading, and the effect these can have on the truck’s chassis.

“It puts weight on the chassis where it shouldn’t, forward or back, side to side, and quite often, if it’s loaded heavy on one side, there’s actually room for dirt on the other side.”

Insights like these are driving conversations around improving utilisation, protecting equipment, and smoothing out inefficiencies that accumulate over time.

Empowering loader operators with 3D load profiling

The team also sees major opportunity in the scanner’s 3D load profiling. Real-time visuals of each load allow trainers and operators to assess balance, detect empty space, and refine their technique.

“It’s one thing that we can use it more in the future is for loader education. Uh, one thing I really like about the newer software is the 3D load profiler…”

It’s a tool that blends performance improvement with long-term sustainability.

Efficiency gains that benefit everyone

For Graham, the value is clear: reducing carryback means more material delivered, fewer wasted litres of diesel, and a lighter environmental footprint. At Macraes, the Loadscan MPS is no longer just a scanner – it’s a catalyst for a smarter, more deliberate, and more productive mining operation.