How volume scanning reshapes customer relationships Tracking material volumes across multiple sites is a [...]

How Loadscan’s LVS Helps Fulton Hogan Improve Earthworks Compliance

Maintaining earthworks compliance is a critical part of quarrying and construction activity in New Zealand, especially in regions with strict resource consent requirements like Queenstown. To support accurate reporting and improved material tracking, Fulton Hogan’s Queenstown quarry has invested in Loadscan’s Load Volume Scanner (LVS) to measure large volumes of clean fill entering the site from multiple major projects, including the Queenstown Airport expansion.

Meeting Resource Consent Obligations

The Queenstown Lakes District Council sets tight guidelines around earthworks management. Quarries must be able to provide accurate, verifiable records of material movement to stay within approved limits.

Accurate Volume Measurement for Regulatory Reporting

The LVS gives Fulton Hogan the tools to confidently meet consent requirements. By precisely tracking incoming loads, the team can maintain compliance, avoid overfill issues, and ensure full transparency with regulators.

Why Fulton Hogan Chose the Load Volume Scanner

Proven Reliability in Local Quarry Operations

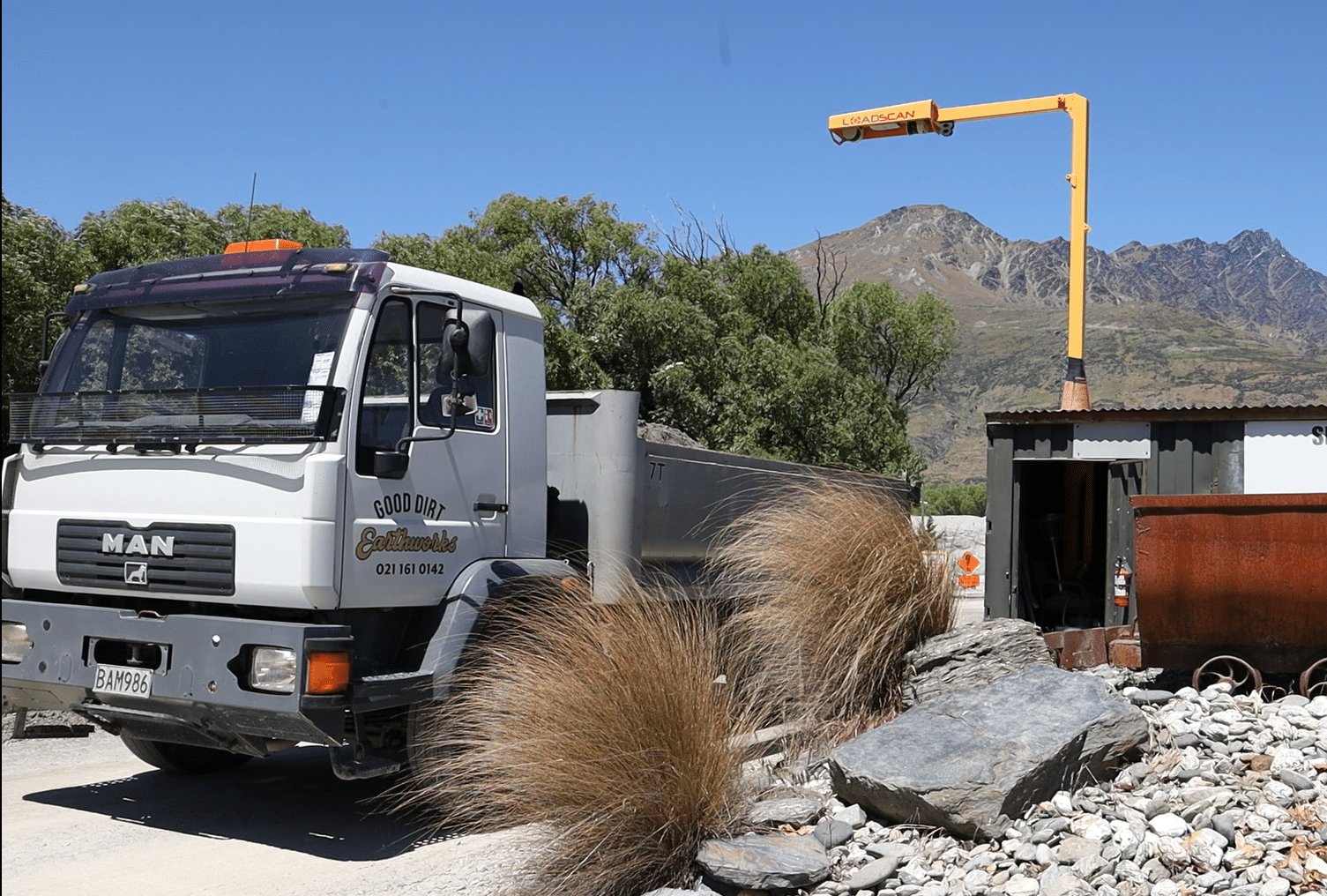

Fulton Hogan’s decision was strongly influenced by their experience using their neighbour’s LVS. Queenstown Hardfill LTD—one of Loadscan’s earliest customers—has been using the technology for over a decade. Seeing consistent performance in a real-world quarry environment highlighted the system’s long-term reliability and value.

Removing Guesswork with Automated Scanning

The LVS eliminates guesswork and human error by using laser scanning, RFID technology, and advanced software to create a true 3D model of every truck and trailer bin. Each automated drive-through scan provides exact volumetric measurement, improving the accuracy of material verification, load tracking, and earthworks reporting.

The LVS-3BMF: A Fixed, Hardwired Solution

Fulton Hogan purchased a block-mount fixed LVS-3BMF.

Instant Access to Live Data

This fixed installation is hardwired to the quarry office, giving operations staff immediate access to real-time load data, streamlining decision-making, and strengthening operational control.

Optimised for All-Weather Quarry Conditions

With an out-of-the-weather operating position, the system is ideal for busy quarry environments where durability and reliability are essential.

Strengthening Earthworks Compliance Across the Industry

For quarries aiming to tighten earthworks compliance, improve material verification, and simplify reporting, Loadscan’s LVS offers a proven, industry-trusted solution backed by more than a decade of field performance.

Explore more about Loadscan’s Load Volume Scanner or browse real quarry case studies on our quarry page.