Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Where every cubic

meter counts

Where every cubic

meter counts

Join the ranks of forward-thinking companies — choose Loadscan for precision, reliability, and efficiency in load measurement

“Buyers and sellers alike struggled to find a consistent method for loading trucks that was fair to everyone. Loadscan has solved all that.”

Dave Boyce, Midwest Trading Horticultural Supplies Inc, USA

Put an end to inefficiencies, waste, and guesswork.

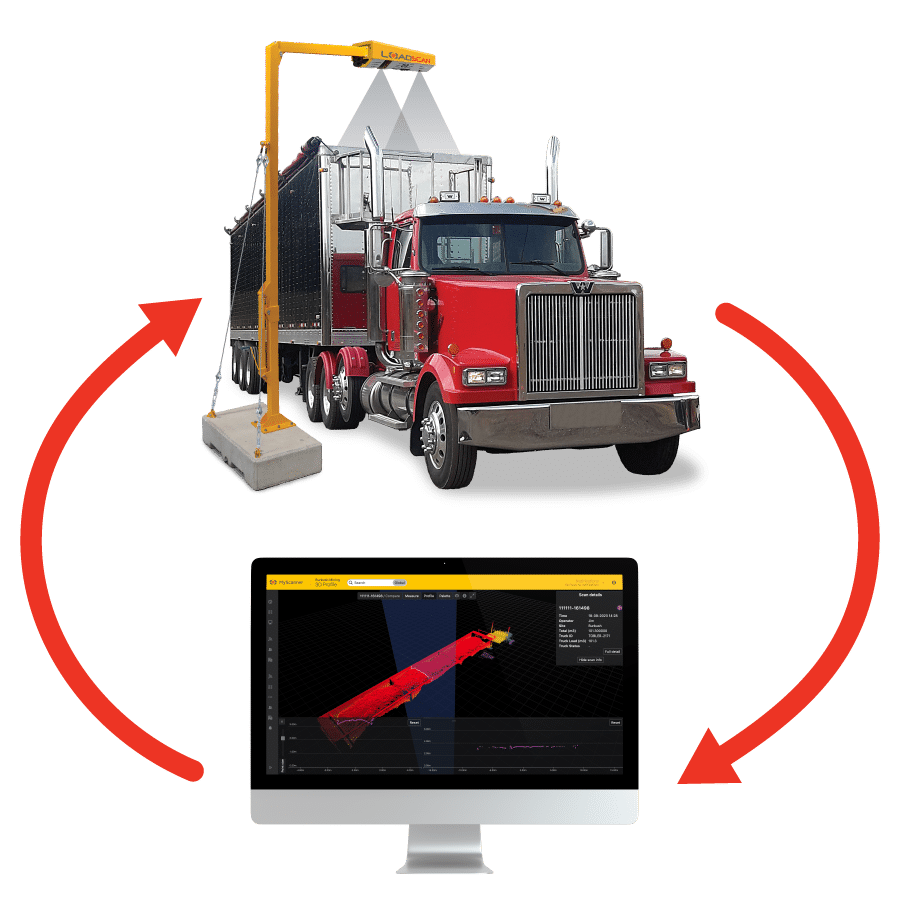

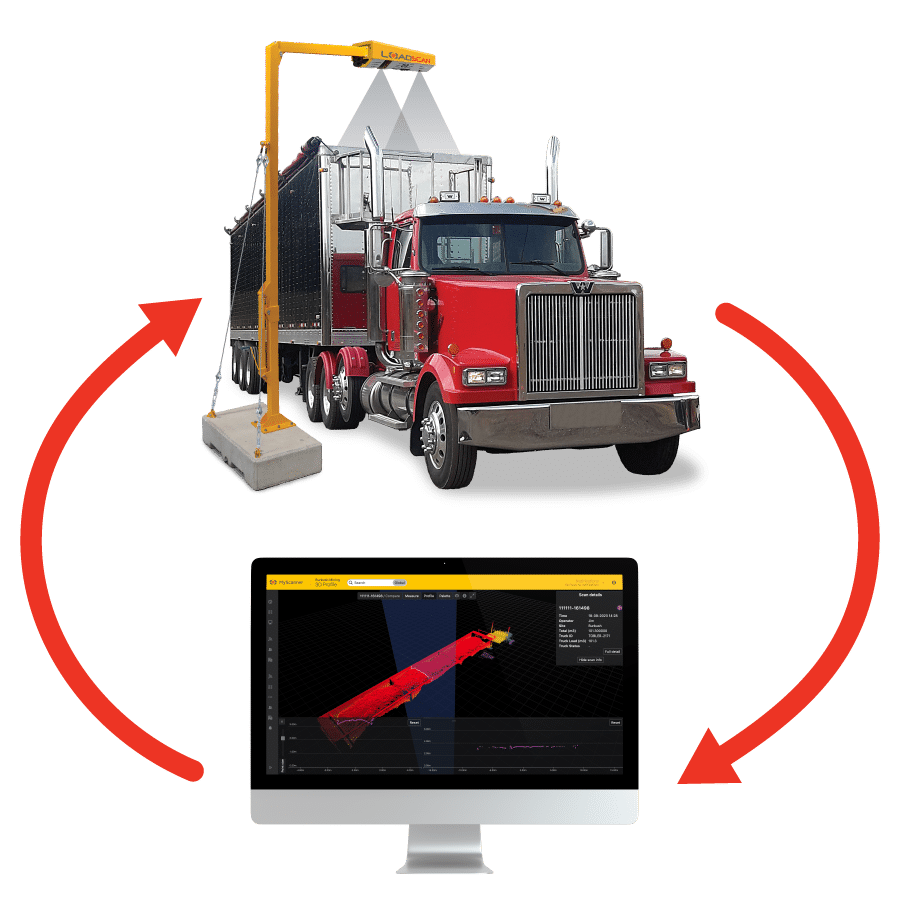

Trucks are scanned by driving below an elevated scan head, which can be mounted on a portable or fixed pole or can be fitted to a trailer. The scanning process is fully automated

Proprietary MyScanner software reports volumetric measurement, including 3D load profiles of every load

Put an end to inefficiencies, waste, and guesswork.

Trucks are scanned by driving below an elevated scan head, which can be mounted on a portable or fixed pole or can be fitted to a trailer. The scanning process is fully automated

Proprietary MyScanner software reports volumetric measurement, including 3D load profiles of every load

Get accurate product densities

Optimise truck loading

Accurate volumes sold every time

Don’t pay for water content