Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Guarantee aggregate supply volumes and manage quarry stripping with ease and accuracy

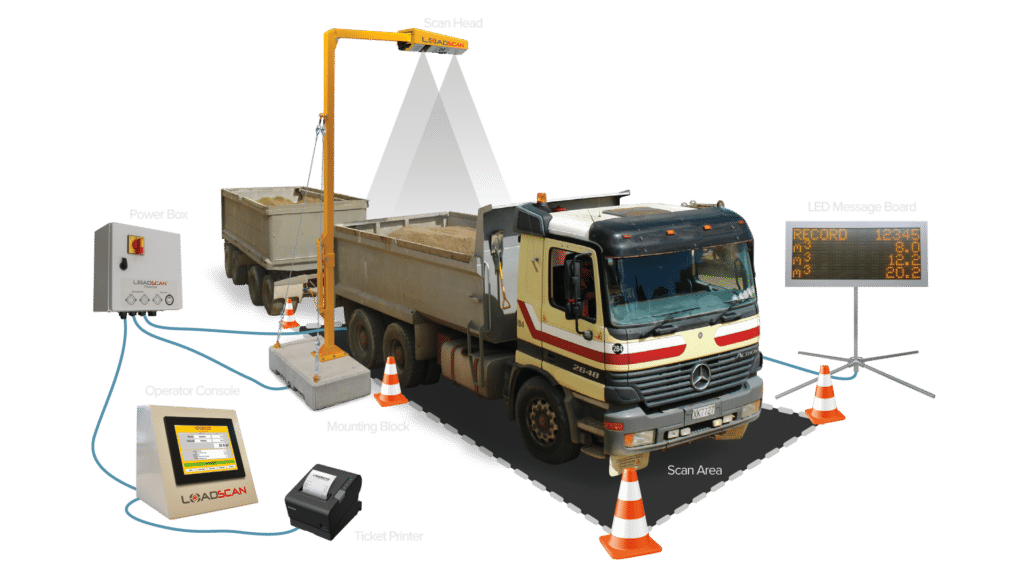

Keeping track of your overburden movements, and monitoring your aggregate deliveries, is a breeze when you utilise load volume scanning technology. Using RFID tags to identify every truck and trailer, you are able to fully automate the scanning process. With a simple drive-through scan, the system will provide a volumetric measurement as well as 3D load profile for every load.

If you’re supplying material to the construction or landscaping industries, then you’ll keep customers coming back by specifying the bulk volumes supplied. They’re used to volumetric measurement and will appreciate the accuracy and assurance Loadscan provides.

Load volume scanning and Loadscan’s load-management reporting system provides you with the full picture of your material movements. You’ll know exactly how much product has been supplied to any given customer and how much material is stockpiled. By accurately measuring overburden carried out of the quarry, as well as the haul-back from every load, you’ll be able to manage your quarry-stripping contracts with accuracy and confidence.

How load volume scanning works

Trucks or trailers drive below the scan head, which can be positioned on their ordinary quarry route. Each vehicle that you’d like to measure can be fitted with an RFID tag for automatic identification and recording. The in-motion scanning process is fully automated and provides accurate volumetric measurement of every load, including 3D load profile, and is detailed by our proprietary MyScanner software. More…

Being customer focused will give you the competitive edge

Your customers in the construction and landscaping industries work in bulk volumetric quantities. So, your ability to supply product by volume (rather than weight or simple bucket-count) will help you win jobs and keep customers happy. Loadscan users are winning large earthworking tenders thanks to their ability to provide accurate supply monitoring as part of their contract.

The load volume scanning (LVS) system can be used either as a stand-alone measurement solution or alongside existing weigh-bridge or on-board loader scales. The advantage Loadscan has over other sand, rock and gravel measurement systems is that it’s low maintenance and enables much smarter product management with powerful software, which can be accessed remotely and interfaced with your office management system.

Load scanning for quarry stripping

Volumetric measurement for aggregate extraction

Customer supply volume guarantee

See how other quarries are using Loadscan load volume scanners and what they’re saying…