Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Micromine and Loadscan join Forces for Real-Time, Precision Payload Management in Mining Operations

Enhanced Accuracy and Efficiency in Material Haulage through Automatic Payload Data Logging

Micromine, a global leader in next-gen technology for mining, is pleased to announce a new partnership with Loadscan, front-runner in volumetric scanning technology. This integration brings together Micromine Pitram’s real-time mine control capabilities with Loadscan’s volumetric Mine Payload Scanner (MPS) under its specialist mining division, Mine Payload Technologies, enabling mining operations to capture and log haulage data automatically and with greater precision than ever before.

With this partnership, we are empowering mine operators to access the most accurate haulage data possible

Through this seamless integration, mining operations can reduce human error in data entry and boost decision-making accuracy with reliable, real-time payload data. This enhanced visibility empowers users to optimize equipment utilization, streamline plant processing, and cut costs by making informed adjustments to asset performance and material management.

“With this partnership, we are empowering mine operators to access the most accurate haulage data possible,” said Brendon Shadlow, Strategic Product Manager at Micromine. “By eliminating manual data entry and potential human errors, we are helping operators make smarter decisions that drive efficiency and improve asset performance”. The integration links Micromine Pitram to Loadscan’s MyScanner platform, where payload data from multiple scanners – each with a unique serial number – can be accessed securely.

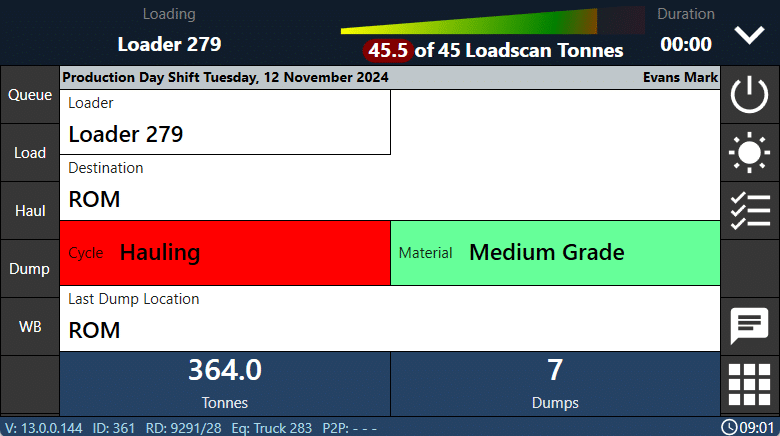

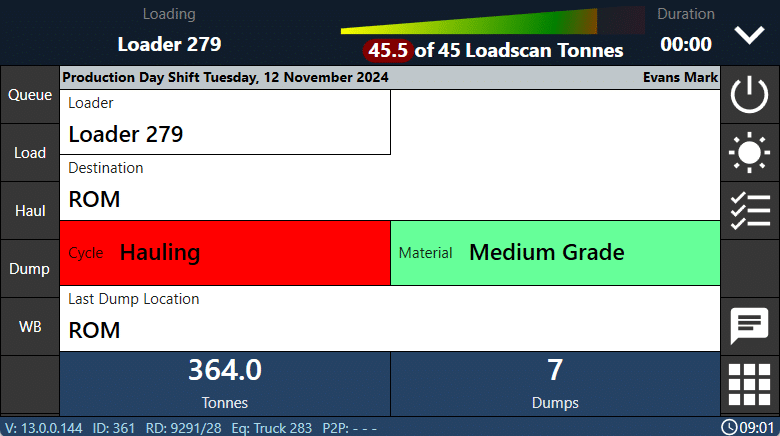

With data on material type and specific gravity (SG) fed into Micromine Pitram, the system calculates the total weight and records payload events. This information is synchronized when trucks dump material, allowing for accurate real-time reporting and a complete record of haulage data.

Carey West, Managing Director of Loadscan highlighted the impact of the partnership: “Integrating our volumetric scanning technology with Micromine Pitram creates a powerful solution for mining operators. By providing precise, automated payload data directly into Pitram, we’re enabling teams to focus on optimizing their operations rather than worrying about data quality. This partnership reflects our shared commitment to driving innovation and efficiency in the mining industry.” For more information, visit www.micromine.com/pitram.

Micromine, a global leader in next-gen technology for mining, is pleased to announce a new partnership with Loadscan, front-runner in volumetric scanning technology. This integration brings together Micromine Pitram’s real-time mine control capabilities with Loadscan’s volumetric Mine Payload Scanner (MPS) under its specialist mining division, Mine Payload Technologies, enabling mining operations to capture and log haulage data automatically and with greater precision than ever before.

With this partnership, we are empowering mine operators to access the most accurate haulage data possible

Through this seamless integration, mining operations can reduce human error in data entry and boost decision-making accuracy with reliable, real-time payload data. This enhanced visibility empowers users to optimize equipment utilization, streamline plant processing, and cut costs by making informed adjustments to asset performance and material management.

“With this partnership, we are empowering mine operators to access the most accurate haulage data possible,” said Brendon Shadlow, Strategic Product Manager at Micromine. “By eliminating manual data entry and potential human errors, we are helping operators make smarter decisions that drive efficiency and improve asset performance”. The integration links Micromine Pitram to Loadscan’s MyScanner platform, where payload data from multiple scanners – each with a unique serial number – can be accessed securely.

With data on material type and specific gravity (SG) fed into Micromine Pitram, the system calculates the total weight and records payload events. This information is synchronized when trucks dump material, allowing for accurate real-time reporting and a complete record of haulage data.

Carey West, Managing Director of Loadscan highlighted the impact of the partnership: “Integrating our volumetric scanning technology with Micromine Pitram creates a powerful solution for mining operators. By providing precise, automated payload data directly into Pitram, we’re enabling teams to focus on optimizing their operations rather than worrying about data quality. This partnership reflects our shared commitment to driving innovation and efficiency in the mining industry.” For more information, visit www.micromine.com/pitram.