How volume scanning reshapes customer relationships Tracking material volumes across multiple sites is a [...]

Micromine and Loadscan Partner to Deliver Real-Time, Precision Payload Management

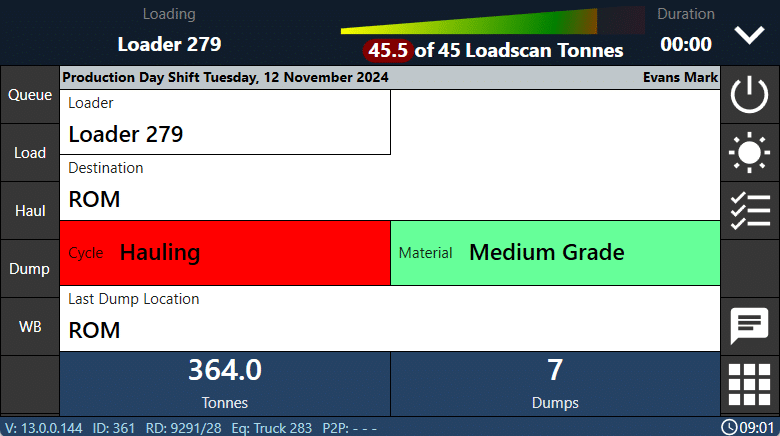

Micromine, a global leader in mining technology, has partnered with Loadscan, the leader in volumetric scanning. This new Micromine Pitram Loadscan integration connects Pitram’s real-time mine control system with Loadscan’s Mine Payload Scanner (MPS). As a result, mining operations can now capture and log haulage data automatically and with far greater accuracy.

This partnership gives mine operators faster insight into load movement, clearer reporting, and more confidence in their payload data.

Automated Payload Logging for Higher Accuracy

The integration removes manual data entry. Because of this, mine teams no longer risk human error in their payload records. Operators can trust the information they receive and respond to it quickly.

“With this partnership, we are empowering mine operators to access the most accurate haulage data possible,” said Brendon Shadlow, Strategic Product Manager at Micromine. “By eliminating manual data entry and potential human errors, we are helping operators make smarter decisions that drive efficiency and improve asset performance.”

The system links Micromine Pitram to Loadscan’s MyScanner platform. Each scanner has its own serial number, which allows sites to organise and access their data securely.

Real-Time Reporting Through Volumetric Scanning

Whenever a truck passes a Loadscan MPS unit, the system captures volumetric data and sends it straight to Pitram. Pitram then calculates weight using material type and specific gravity (SG). It also logs the payload event. When the truck dumps material, the system updates the record instantly. Consequently, operators receive accurate, real-time haulage information at every stage.

This full chain of visibility helps teams analyse fleet performance and track material movement with confidence.

Better Visibility, Control, and Efficiency

Because the data is reliable and immediate, mine sites can adjust their operations faster. They can improve equipment utilisation, streamline processing, and reduce costs.

Carey West, Managing Director of Loadscan, explained: “Integrating our volumetric scanning technology with Micromine Pitram creates a powerful solution for mining operators. By providing precise, automated payload data directly into Pitram, we’re enabling teams to focus on optimising their operations rather than worrying about data quality.”

This partnership reinforces both companies’ commitment to innovation and operational excellence.

A Strong Step Forward for Digital Mining

The Micromine Pitram Loadscan integration delivers a modern and accurate payload management solution. With automated data, real-time scanning, and stronger visibility, mining operations gain the clarity they need to make fast, informed decisions and lift performance across the entire haulage cycle.

This partnership reflects our shared commitment to driving innovation and efficiency in the mining industry.” For more information, visit www.micromine.com/pitram.