Bin shape cause haul back?

Are your trucking factors compromised because the shape of the haul truck bin exacerbates haulback?

From our experience we have seen bin shape that causes haulback, creating an over stating of haul truck production when in reality, it’s a short fall in production.

This raises the cost per tonne to haul the material.

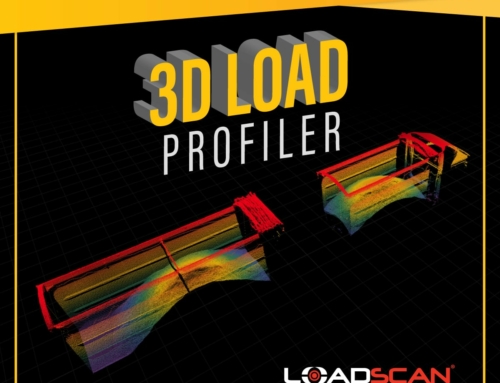

The Loadscan 3D Payload Profiler gives a graphical load representation for visual load shape and distribution feedback as well as an indicator that the load has been hauled.

How it works…

1. Each truck is assigned with an RFID tag for automatic identification.

2. The trucks are scanned empty to provide baseline stats in the load volume scanner.

3. Bins are filled.

4. Trucks drive under the scan head and are automatically scanned with volume measurements recorded.

5. The truck can be scanned on the return trip to check if haulback/carryback stuck is present in the binand this can be removed from the shift Tally.

6. Using the 3D load profiler performance of the truck bin can be assessed to check for efficiency and to monitor when the bin needs to be cleaned out.