Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Ensure you only pay for the material you receive

Variations from initial material volume estimates and final in-place volumes often occur, resulting in cost overruns, construction claims, disputes, budget waste and added administrative costs.

With a Loadscan LVS system you’ll end supply disputes. If you purchase or supply construction materials in cubic volume then it makes sense to manage and account for infill delivered to site using a common method, because disputes over supply can be frustrating, time consuming and expensive.

Traditional methods of determining truck load volumes, including converting from weight, counting loader buckets, or simply counting trucks, are inaccurate and contribute to supply disputes. Survey quantities don’t account for bulking factors in material loaded into a truck from a cut, nor compaction of the material when it’s unloaded at a fill site.

Volumetric laser scanning is the only accurate and consistent method for measuring truck loads.

Underloading costs civil operators a fortune

Underloaded trucks can significantly increase overall project costs, and it’s not uncommon to see underloading factors as high as 20%.

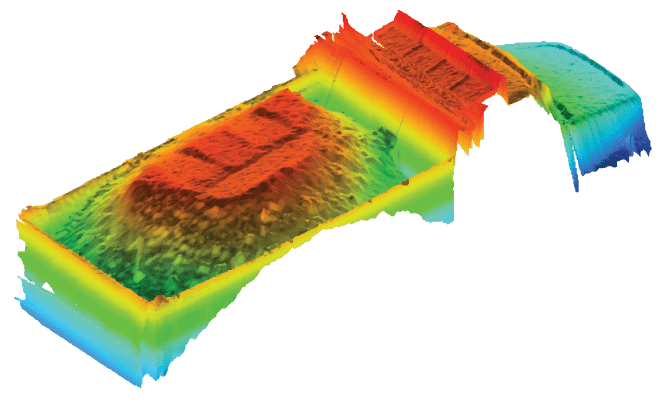

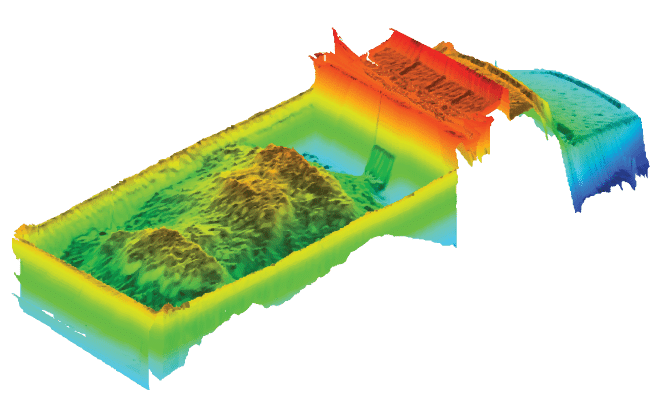

With automatically generated 3D scans of every load you can identify poor loading practices and use the information to coach and train loader operators.

By optimising loading you’ll maximise the value of every contract. In addition, knowing that you’re accurately measuring and optimising your truck capacity will enable you to be more confident when preparing project bids.

Optimally Loaded: 14.1yd³ payload = 46,100 truck loads

Underloaded: 11.9yd³ payload = 54,622 truck loads

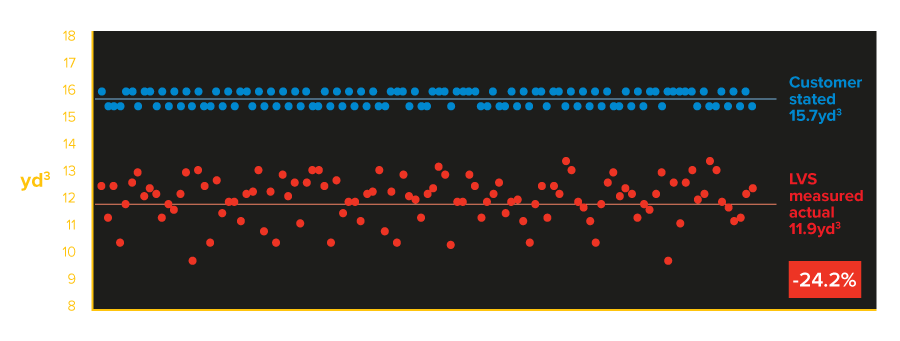

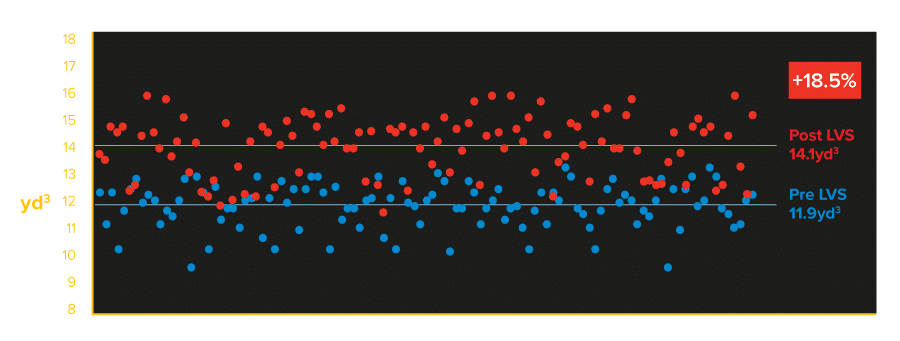

The following load performance scatterplots illustrate how one customer improved loading with the implementation of the LVS system.

Load Volume — Stated vs Measured

Customer-stated volumes were over-reported by 24.2% when measured against actual load volumes scanned with the Loadscan LVS.

Load Volume — Pre vs Post LVS

After implementing the Loadscan LVS, actual loaded volumes increased by 18.5%. The scan data enabled operator training and coaching to be carried out, improving loading practices.

Underloading requires 8,522 additional truck loads to shift 650,000yd³

Volume scanning delivers extensive benefits for civil operators

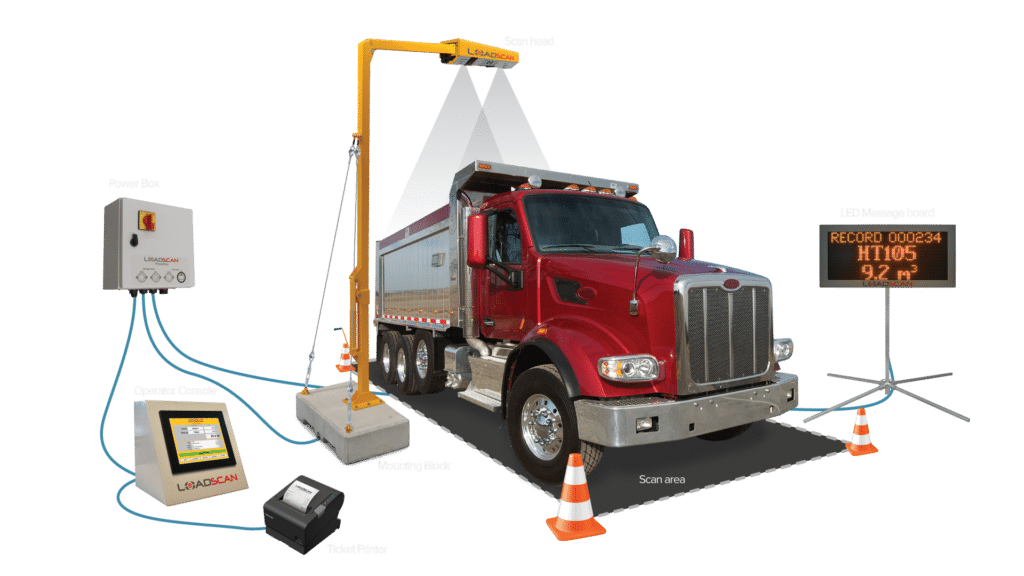

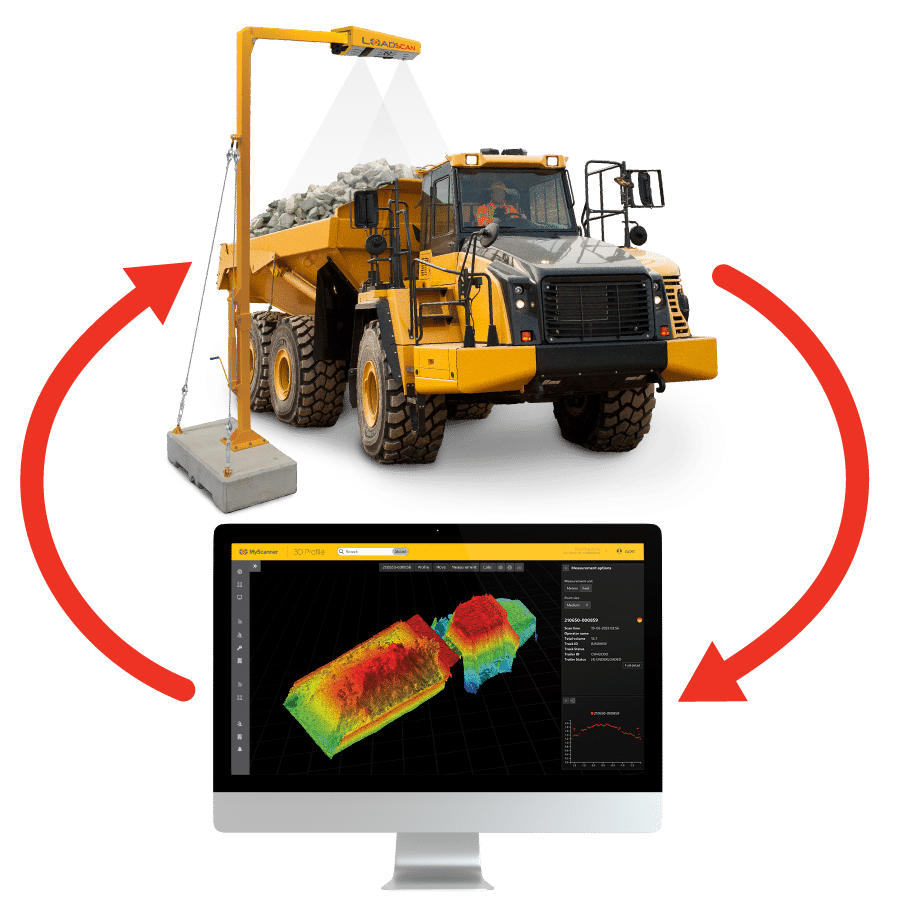

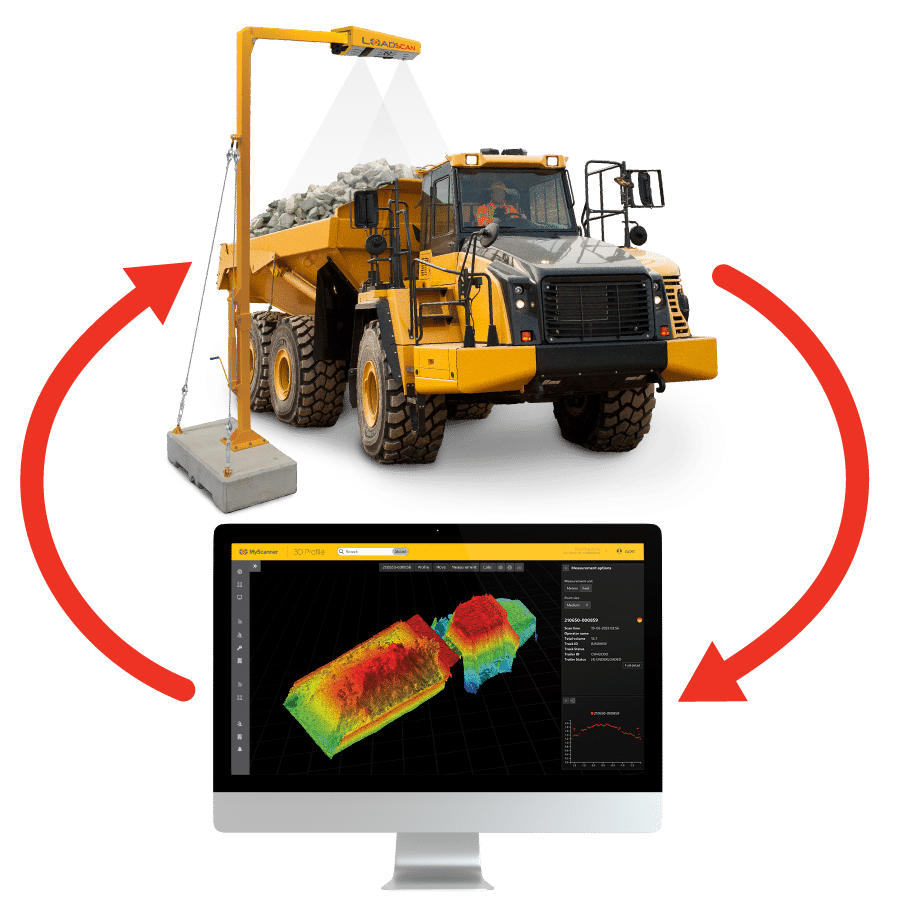

How the LVS system works

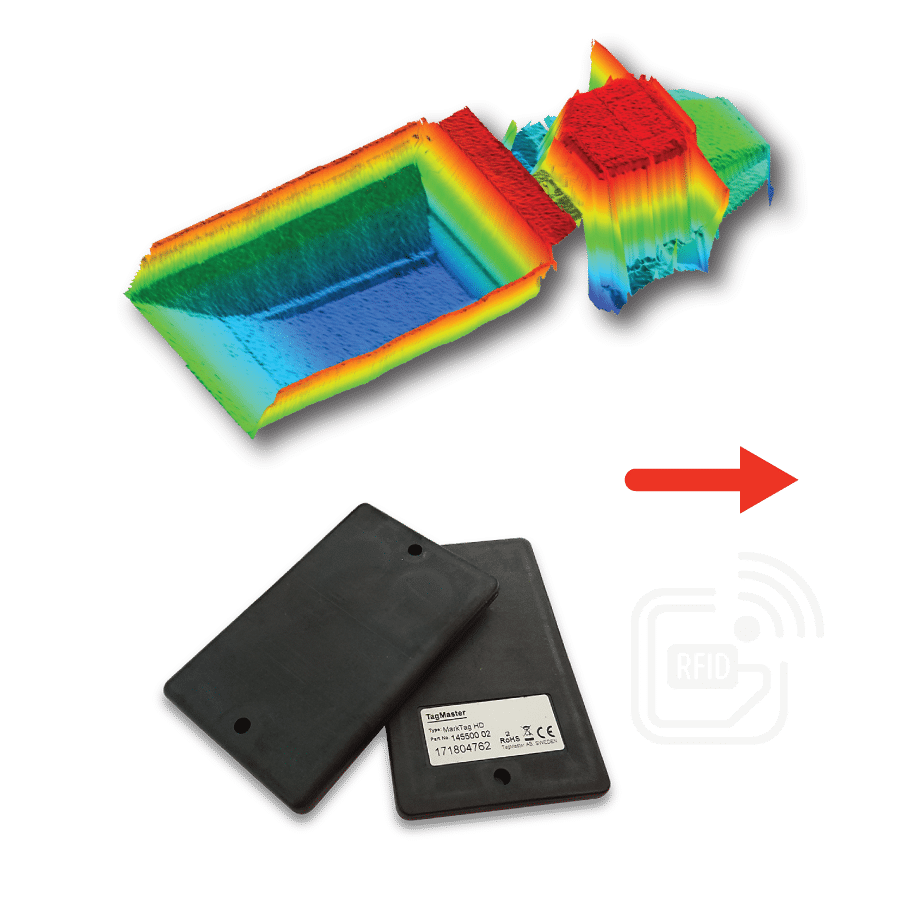

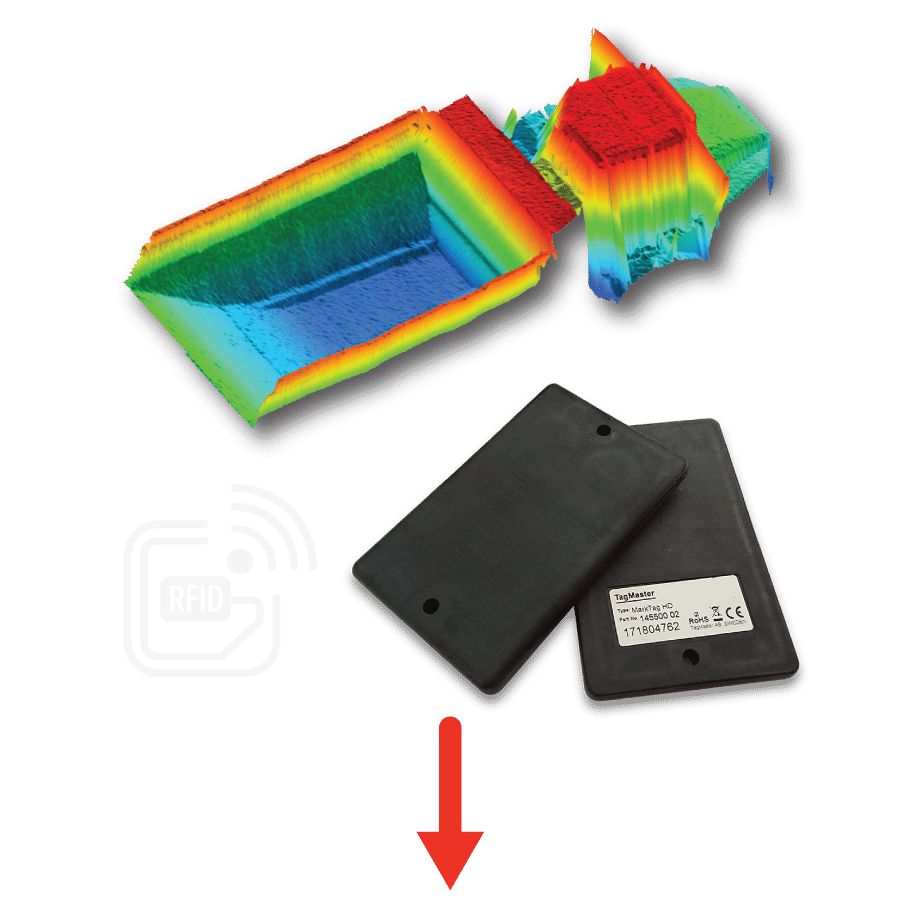

Empty truck is scanned to create reference scan in the database

Trucks are scanned by driving below an elevated scan head, which can be mounted on a portable or fixed pole or can be fitted to a trailer. The scanning process is fully automated

Trucks can be tracked manually or fitted with RFID tags for automatic identification

Proprietary MyScanner software reports volumetric measurement, including 3D load profiles of every load

How the LVS system works

Empty truck is scanned to create reference scan in the database

Trucks can be tracked manually or fitted with RFID tags for automatic identification

Trucks are scanned by driving below an elevated scan head, which can be mounted on a portable or fixed pole or can be fitted to a trailer. The scanning process is fully automated

Proprietary Overview software reports volumetric measurement, including 3D load profiles of every load

See how other civil construction businesses are using Loadscan load volume scanners.

Loadscan’s load volume scanners are being used successfully by civil operators across the globe.

Click on the case studies to see how these Loadscan customers are benefiting from volumetric scanning…