Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

The world continues to struggle under the social strain and economic fallout of the COVID-19 pandemic, with many industries negatively impacted and some devastated. However, amidst the economic doom and gloom are many positive stories of businesses that are thriving despite the odds.

Loadscan closed the 2020 year with a record order book. Carey West, Loadscan CEO says, “Throughout 2020 we experienced a marked increase in enquiries across all of our target industries right through to the Christmas break, with mining and civil construction leading the way.” He adds that Loadscan had also received strong enquiries from the bark, mulch and compost sectors. Interestingly, the increased demand has come from every corner of the globe.

A common thread in discussions with potential customers as well as current Loadscan users is the drive to cost-effectively increase productivity and maximise operating profits in an increasingly tough economic environment. Mine operators have traditionally relied on legacy measurement methods and technologies for determining material volumes in their trucks, and prior to the economic squeeze of 2020 were more tolerant of some measurement inaccuracy and the subsequent underloading of trucks. With the tightening economic conditions they have been forced to re-evaluate every aspect of their business, ensuring that production assets are fully optimised.

Results of numerous load audits conducted by Loadscan, as well as feedback from current customers, suggest that trucks are often underloaded by between 5% to 15%. The company has even seen trucks underloaded by as much as 25% in some extreme cases. In many of the enquiries and subsequent orders received by Loadscan, mine operators have cited sub-optimal loading as the biggest issue requiring attention.

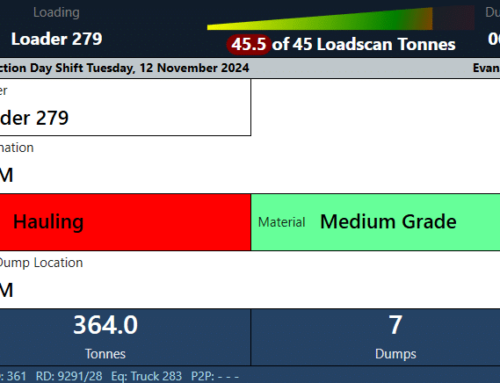

Volume Scanner (LVS) helps mines to optimise loading by maximising every load, thereby increasing trucking factors and improving profits. Their load scanner accurately measures all loads and automatically generates 3D scan images that clearly indicate underloading, enabling corrective action (including operator training and coaching) to be taken. The system is equally suited to underground and surface operations, with a range of fitment options to suit.

Carey West believes that 2020 marked a turning point in the market, where load volume scanning technology achieved mainstream acceptance as a robust and accurate load measurement system. In many cases, customers have integrated their traditional weight-based systems with volume scanning, thereby enhancing measurement accuracy and improving production accounting.

With the global economy still suffering due to increased Covid-19 infections, Loadscan sees 2021 as a year when many more mines across the world turn to load volume scanning in an effort to maximise production returns.