Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Load Volume Scanning Movement in Mexico

With over 250 private exploration companies in Mexico, mining productivity is of huge importance to the country. Mining operations, which are primarily focused in the northern states of Sonora, Zacatecas and Chihuahua, are turning to load volume scanning to increase trucking factors and optimise profitability.

Loadscan’s Mexican customers include the likes of Couer Mexico (a silver mine located in Chihuahua), Penoles (a gold mine located in Chihuahua) and Minera Roble (a silver mine located in Durango).

The load volume scanning (LVS) system comprises a laser scanner and proprietary load management software called Overview. Each system is configured to the customer’s unique operation and can include optional extras like in-cab consoles and bespoke mounting structures.

All LVS systems include RFID readers. Each truck can be assigned an RFID tag, allowing every vehicle to be automatically identified as it drive under the laser scan head. Resulting in full traceability of ore extraction data.

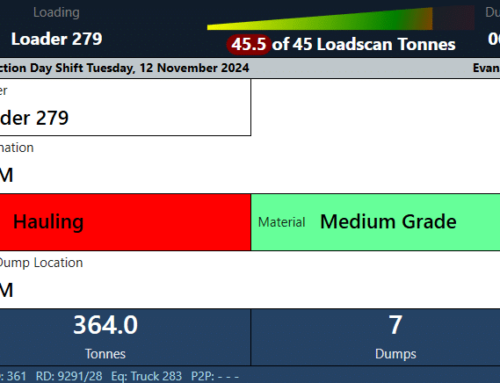

Carey West, Loadscan’s managing director, says “Scanning takes place on the trucks’ normal haul route; they’re automatically scanned and accurate payload volume measurements are recorded.”

“This information is then passed onto the truck’s driver, providing immediate instruction on whether to take the ore to processing or waste.”

The Loadscan load profiling system provides real-time data, including 3D imaging, of every load so loads are optimised, sub-optimal loading is easily avoided, and loader operators are trained to deliver safe, maximised loads. Loading is monitored.

Scanning trucks on their return routes allows mines to monitor and manage wasteful carry-back. And the Loadscan system includes tray clean-out messaging and negative total adjustments to enable mines to reveal their true shift tally after accurately accounting for carry-back.

Mexico has a mining history extending almost 500 years and is among the world’s largest precious metal producers. It is the world’s largest producer of silver and a top producer of gold, copper, and zinc.

Mexican miners wanting to take advantage of autonomous payload management should contact Loadscan’s local representative Luid Asuara at Ingenieria Electronica Equipos Electicos or contact Loascan HQ directly on +64 7 847 5777 or sales@loadscan.com.

The Loadscan® Load Volume Scanner (LVS) system utilizes laser scanning technology combined with proprietary Loadscan software to measure the exact volume of the material loaded in a truck or trailer bin. It provides 3D images and insightful data in real-time for every load; equipping users to optimize truck loading and productivity.

Carey West and his team at Loadscan have successfully built upon the volumetric scanning technology his father originally pioneered, and are now fielding global interest for their market-leading product. Loadscan’s autonomous payload scanning system has been adapted to underground mining with custom-mounts, there is a 24-hour solar-powered load scanner in operation in Africa, and the innovative product’s use and application is booming.

For further editorial information please contact:

Emma Alsemgeest on +64 27 941 5210 or email emma@loadscan.com.