How volume scanning reshapes customer relationships Tracking material volumes across multiple sites is a [...]

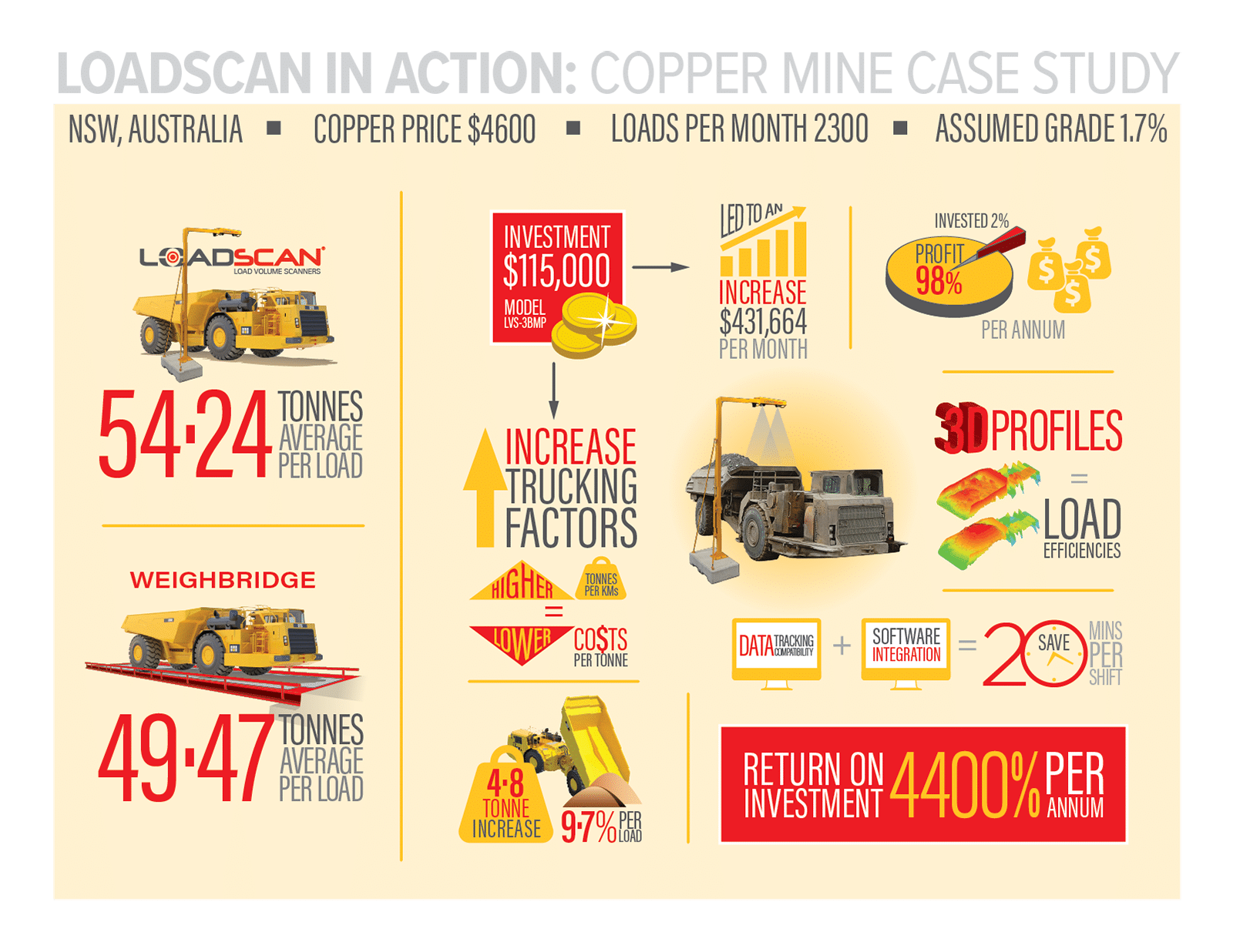

How a Truck Load Measurement System Boosted Tritton Copper Mine’s Trucking Factors by 9.7%

Revolutionising Load Accuracy in Underground Mining

Aeris Resources’ Tritton Copper Mine in Nyngan, New South Wales, made history as the first underground mining operation in Australia to implement Loadscan’s truck load measurement system. As a result, the mine achieved a 9.7% increase in trucking factors, improving efficiency and production performance.

Before adopting Loadscan’s Load Volume Scanner (LVS), Tritton struggled with inconsistent payload data and outdated manual tracking. The previous method relied on paper-based logs and weighbridge readings, which were time-consuming and often inaccurate. Operators manually recorded load times, destinations, and weights. Later, this information was entered into a database—a slow process prone to human error.

Replacing Manual Tracking with Real-Time Volume Measurement

The truck load measurement system has transformed this process. It uses 3D laser scanning and RFID technology to measure the true volume of material in each truck or trailer bin. Because the scanner is non-contact, it avoids the wear and tear common with weighbridges. Consequently, maintenance costs are lower and reliability has improved.

Matthew Gouldstone from Tritton Copper Mine explains:

“The scanner receives no wear and tear as it is scanning rather than weighing and is far more durable given the underground conditions.”

This digital, contact-free system has given the mine accurate, real-time production data. Now, supervisors and operators can make informed decisions faster and with greater confidence.

Delivering Measurable Gains in Efficiency and Productivity

Tritton Mine has seen two major improvements since introducing the truck load measurement system.

1. Real-time feedback and load optimisation

Supervisors now receive immediate load data. As a result, they can coach loader operators to improve truck filling. This feedback loop ensures trucks are loaded to capacity. The change directly led to a 9.7% increase in trucking factors and a lower cost per tonne hauled.

2. Simplified data tracking and reporting

Loadscan’s load profiling software makes it easy to monitor cycle times, shift performance, and tonnes moved. Supervisors now save up to 20 minutes per shift by avoiding manual record checks. In addition, the improved data visibility allows management to make better, data-driven decisions.

Rapid Return on Investment

The benefits of Loadscan’s truck load measurement system were clear within the first month. It delivered measurable gains so quickly that the system paid for itself almost immediately.

For the Tritton Copper Mine, this innovation is more than just a measurement tool. It represents a move toward digital mining efficiency, payload accuracy, and sustainable operational performance.