Cutting haulback means million dollar savings for Rodney Aggregates

Rodney Aggregates Supplies use a load volume scanner (LVS) in their Whangaripo Quarry north-east of Warkworth, New Zealand, to minimise profit loss due to haulback on their overburden stripping programmes. The Whangaripo Quarry is a regular supplier of high-quality greywacke products (asphalt and concrete aggregates through to base courses and bulk fill) to the North Auckland region.

Daniel Le Roux, Business Manager at Rodney Aggregates, says, “The scanner was measuring significant amounts of haulback by the contractor. Especially this season where the material was sticky and wet compared to previous years. This was often up to 5mᶾ per load, which on some trucks is 20-25% haulback – obviously a huge saving for us.”

They strip up to 2,500mᶾ of overburden material a day and if Rodney weren’t using the Loadscan LVS they wouldn’t be aware of the haulback in the truck bins, which influenced the final payments to the contractor. In the years they surveyed volumes and compared them with truck load count, haulback was never considered an issue, although it was present. A discrepancy was subsequently found between survey and truck count volumes. In terms of financial cost, if 20% of a truck load is haulback then the business suffers $3,250 per day cost for material not hauled. Over their six-day working week that’s $19,500. Over a five year period that’s a saving of $4,875,000 in haulback alone.

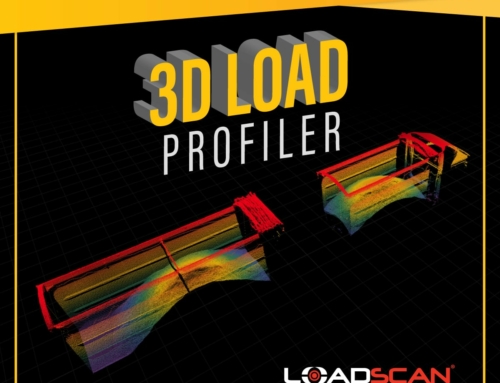

Loadscan’s LVS system utilises laser scanning combined with proprietary software that creates 3D model images of trucks to measure the exact volume of material loaded in a truck or trailer bin. Every system includes an RFID reader for the automatic identification of each vehicle, every load.

Not only does an LVS system enable proper management of loading and haulback, but having highly accurate measurement of every load also gives users an auditable trial of transparent data.

For Rodney Aggregates that data has eased invoicing tensions. Le Roux says, “In the past we used to rely on an aerial survey to calculate volumes moved. This meant that during the season the payments/measures were based on load counts and the final payment was sorted at the end of the season after completing the final flyover. There were usually arguments over final amounts, so final payment was sometimes 0nly agreed up to three months after completion of the works. This affected cashflows negatively”

Loadscan’s LVS system is completed by load-management reporting system called Overview, which provides Rodney Aggregates with the full picture of material movements on-the-fly. They are now equipped with accurate real-time information that allows them to monitor exactly how much product has been stripped by their earthworks contractor.

Le Roux says, “Another great benefit is having the data of loads/volumes available in real-time in front of me. It makes monthly payments accurate and reliable – no arguing with the contractor on volumes moved.”

The LVS model used by Rodney Aggregates is Loadscan’s mobile truck scanning solution (LVS-3TMM). The fully self-contained mobile truck measurement unit is driven to site and fully setup and operational in as little as 45 minutes. There are a range of power options, plus the ability to transmit truck measurement load reports via Wi-Fi, cellular modem or network cable.

The scanner, with extended rigger, is set up to measure the 40T articulated dumpers removing overburden from the quarry. Rodney Aggregate’s LVS is equipped with a built-in kiosk so that it’s fully self-contained. Overview reporting software is used to process and sort scan data and to generate custom load reports. And the office is equipped with LVS remote control functionality via network cable/WiFi/cellular modem.