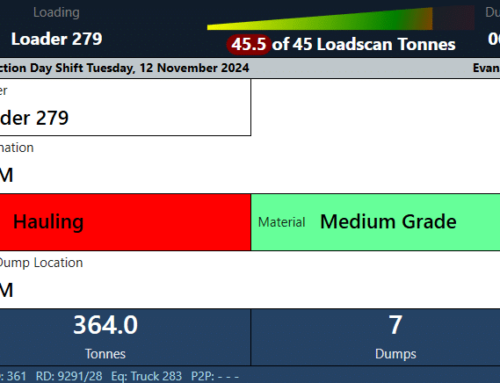

Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Part two – real results from a Brisbane based construction company.

Missed part one? Read it here.

This report illustrates, by utilising the Loadscan system, what commercial benefits exist and how the system can be used to monitor improvements in loading consistency, productivity and management of overloads for road legal requirements.

Density

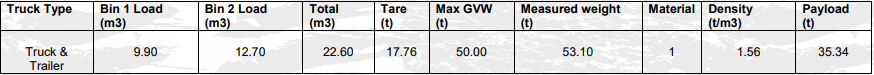

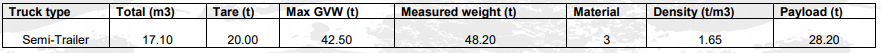

Results from the Loadscan volume scanner and gross weights taken on a public weighbridge for selected trucks enabled the calculation of loose material density for specific material types. The table below shows the different density values for the three materials measured while onsite.

Material 1

Material 2

Material 3

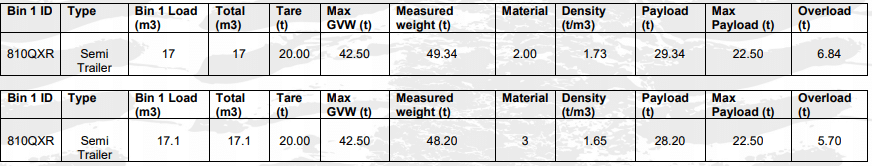

Overloading

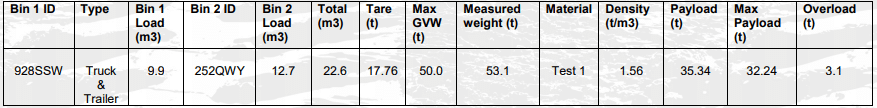

With the density factor applied to the measured volume a payload value in tonnes can be calculated for each load. Below are the calculations for the truck units that were weighed at the weighbridge. Initial results showed that trucks were loaded over their maximum load limits in all materials sampled.

Truck and trailer

Semi-trailer

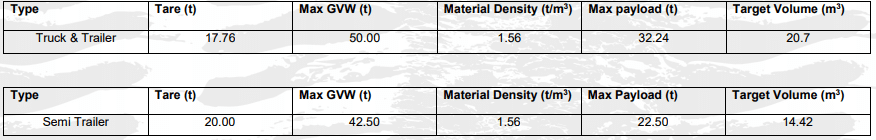

Target volume

Target volume to manage truck mass load limits for road compliance The tonnes calculation enables management of maximum mass load limits for each particular truck configuration. Loading to target volume using an accurate material density value will reduce the risk of overloading in relation to the trucks maximum allowable load limits and be in compliance with DTMR. Below are some examples of calculated target volumes based on a known material density value and the trucks maximum mass limits.

Summary

• Loadscan’s load volume scanning system has proven to be a more accurate measurement of material

movements when compared to traditional methods.

• Big opportunities to reduce export carting costs and increase your profit.

• Billing carting company for m³ measured not assumed.

• Big improvements in loading consistency and productivity.

• Semi trailers are the least productive when compared to truck and trailers.

• Use volume data and weighbridge results to calculate loose material density.

• Apply density values to material types to calculate tonnes.

• Load to target volume to manage truck specific mass load limits.

• Compliance with mass load limits will reduce the risk of fines for overloading.

• Chain of responsibility.