Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Truck congestion issue solved with load volume scanner

Brad, our Product Design Engineer made a recent visit to Indonesia to install two load volume scanners (LVS) with Loadscan’s Overview Software to PT Binas Indo Raya Mine. The mine installed a scanner because its weigh bridges were too slow – causing slow movements and unnecessary truck congestion.

How does the load volume scanner work?

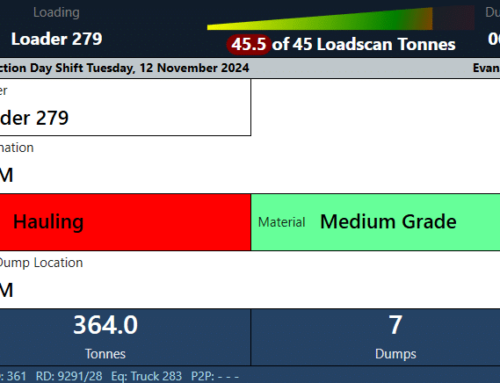

With an RFID tag reader assigned to every truck, the trucks are scanned by driving below the scan head (without stopping). The scanning process is fully automated and provides volumetric measurement of each load.

With a translator onsite Brad was able to train the staff on how to use the scanners and give detailed training on the software. With Brad’s help the staff were able to test the system with the trucks they had available to demonstrate the abilities of the scanner.

By scanning the trucks empty first and returning for a full loaded measurement there was data available in Overview to analyse. Overview software retrieves the measurement records from the LVS enabling the staff members to view, edit, sort and filter records in Microsoft Excel – equipping them to optimize truck loading and productivity.

Loadscan travel worldwide to support our customers installs.

Find out how Loadscan can measure material for your mine, quarry, civil construction site and bark and mulch facility.