Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Why choose an LVS over scales?

Below we have five quick and easy reasons why the load volume scanner (LVS) system trumps conventional truck scales.

Portability and simplicity of installation

With a quick setup process, the LVS is fully portable and can be integrated in many settings. May it be for mining, quarries, bark and mulch, or civil construction.

In-motion scanning

The LVS is intended to scan truck loads while they pass under the laser scanning head. The LVS gives a graphical load representation for visual load shape and distribution feedback. It allows operators to detect off-centre or unsafe loading, load fragmentation and general load shape resulting in increased productivity for many users.

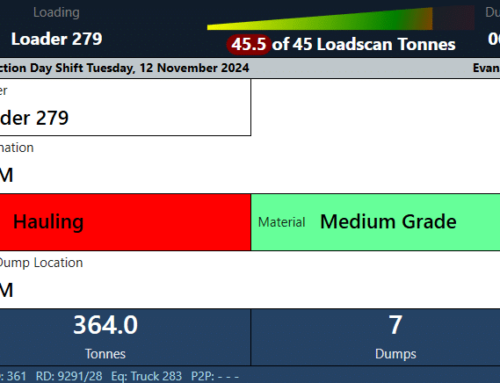

Load position monitoring

You can reduce tyre and machinery wear, increase truck fill factors and improve payload safety with load distribution graphics and statistics for performance monitoring to visually educate and train operators in optimizing payload efficiency. Make manual measurements of load features or truck body dimensions with point-to-point measurements on longitudinal and transverse scan data cross-sections.

Cost-efficient

Not only does it cost far less than conventional scales, the cost savings gained from the efficiency of the LVS is huge!

Easy management

The LVS uses a the Overview Load Management Software utility for retrieving measurement records from your LVS, viewing, editing, sorting and filtering records and generating summary period reports in Microsoft Excel®

Click here for more information on Loadscan’s Load Volume Scanner.